5052 Aluminum Plate Sheet

5052 Aluminum Plate Sheet

Product Features:

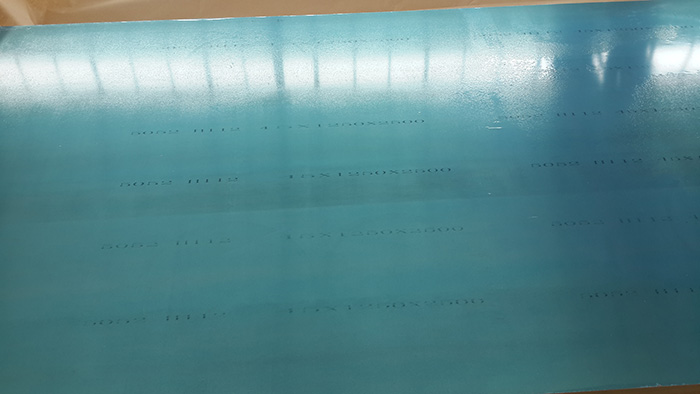

1.Very good surface and

polished bright surface, Excellent flatness control to the product

;

2.Paper interleave / single

side or both sides PE coated for good surface protection ;

3.Excellent anodizing

quality, excellent mechnical property ;

4.Well-protected packing

;

5.Stonger than 1*** and 3***

series aluminum ;

6.The best welding

characteristics out of all the aluminums ;

7.Good formability, good

resistance to corrosion .

HWALU

Aluminium’s 5052 Aluminum alloys plate sheet offer a remarkable spectrum

of design opportunities to benefit consumer electronics manufacturers. The light

weight materials enable you to trim precious ounces, coupled with high strength

to make smaller, thinner components attainable. But while they score high marks

for function, these alloys also take on an outstanding variety of looks and

feels — a multitude of alternatives for creating and updating handheld

devices and technologies for the home.

Aluminium alloy

5052 alloys plate sheet contains nominally 2.5% magnesium & 0.25% chromium.

It has good workability, medium static strength, high fatigue strength, good

weldability, and very good corrosion resistance, especially in marine

atmospheres. It also has the low density and excellent thermal conductivity

common to all aluminium alloys. It is commonly used in sheet, plate and tube

form.

Typical Applications

Architecture, general sheet metal work, heat exchangers.

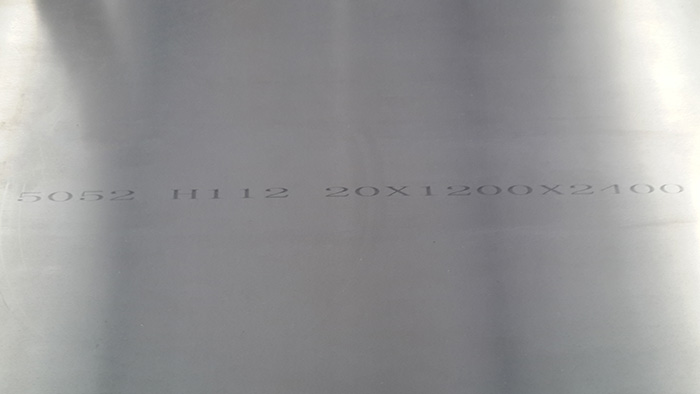

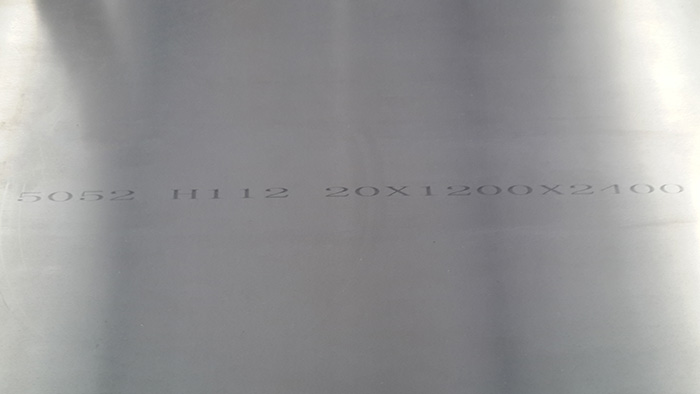

Alloy: 5052

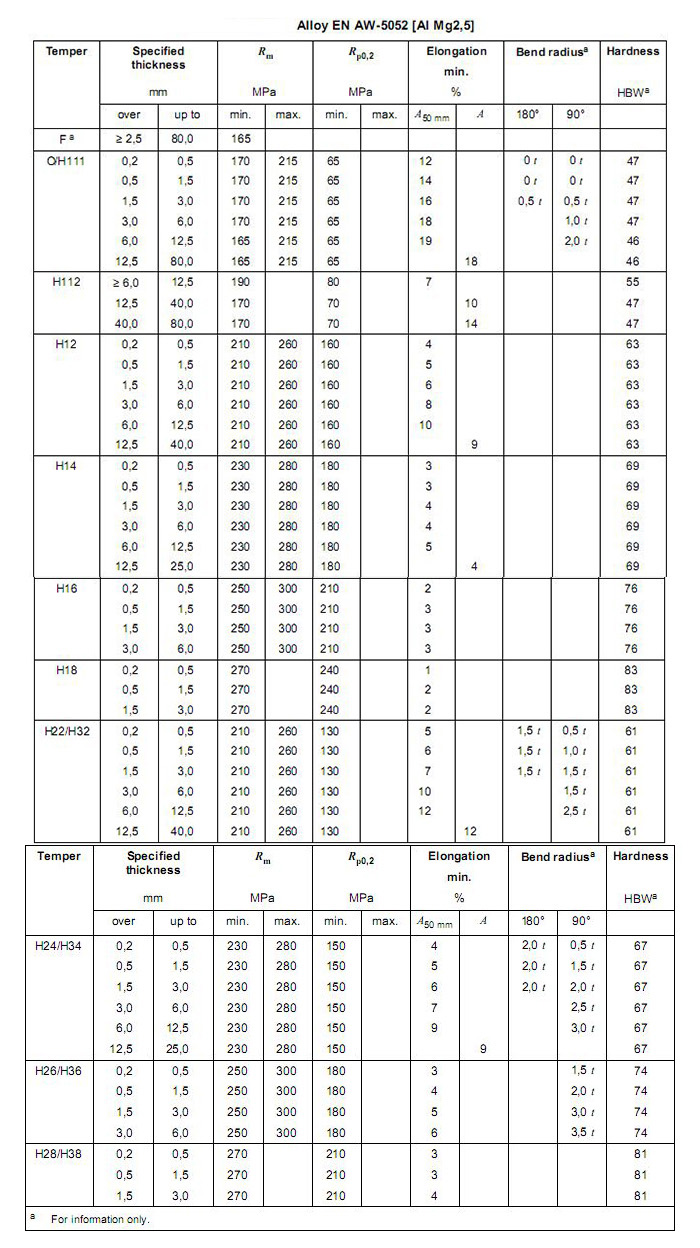

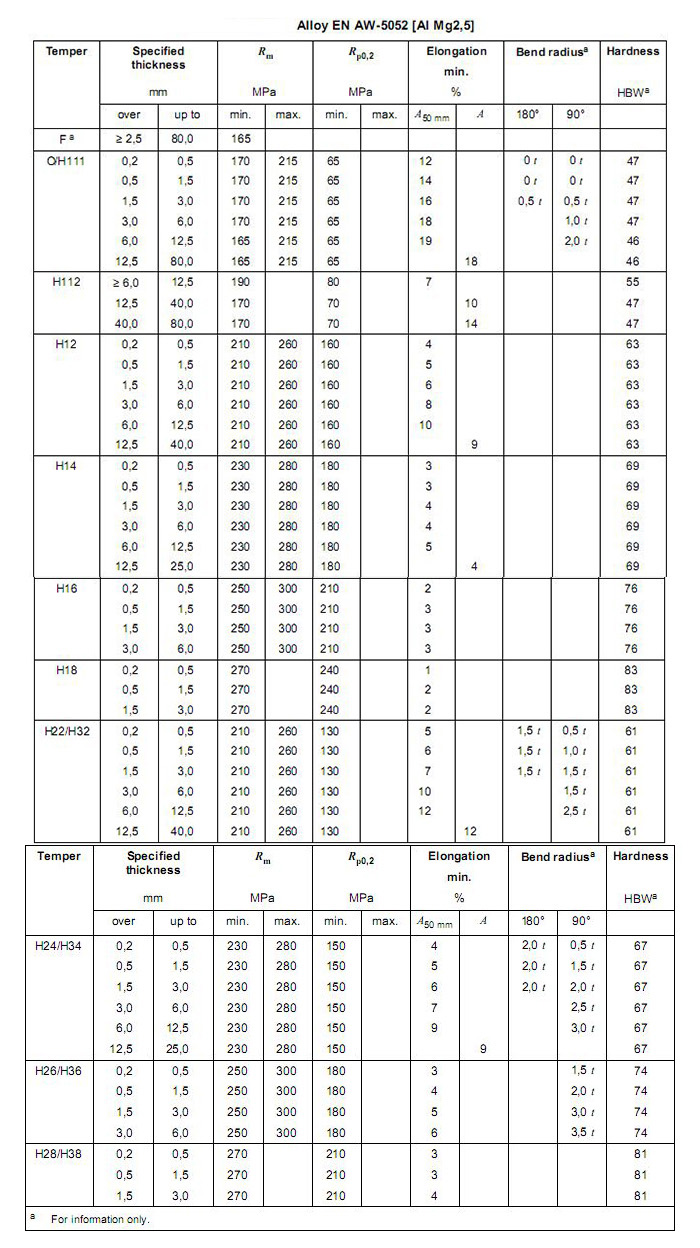

Temper: O, H111, H112,

H12,H14, H16, H18, H32, H34, H36, H38

Thickness:

0.2mm--200mm

With:

500mm--2800mm

Length:

1000mm--12000mm

Surface: Mill finish, Bright

finish, paper interleaved, one side film, both sides film.

Chemical Properties

AluminumAluminiumplatesheet.jpg)

Chemical Properties

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Ni | Zn | Ti | Ga | V | Others |

Aluminium min. |

|

| Each | Total | |||||||||||||

| 5052 | 0.25 | 0.4 | 0.1 | 0.1 | 2.2-2.8 | 0.15-0.35 | - | 0.1 | - | - | - | 0.05 | 0.15 | Remainder |

AluminumAluminiumplatesheet.jpg)