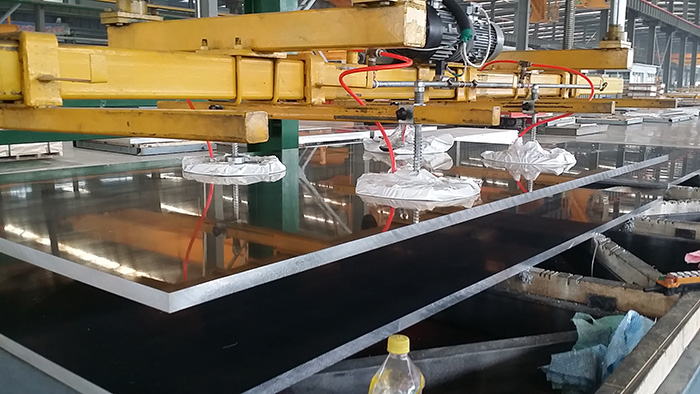

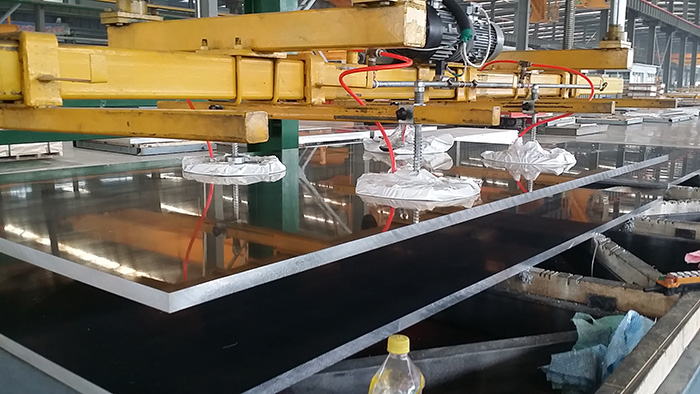

2124 Aluminum Plate Sheet

2124 Aluminum Plate

Sheet

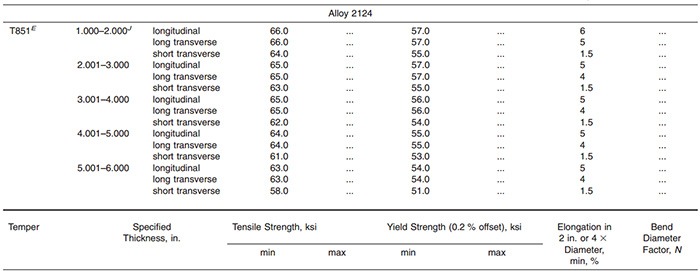

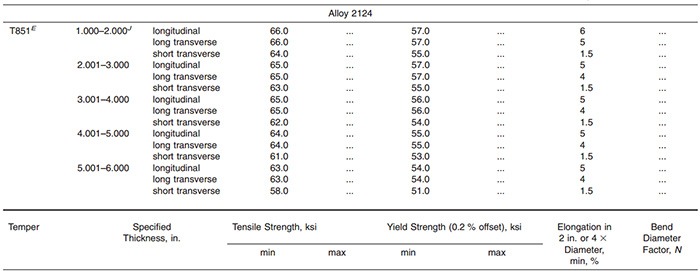

Alloy 2124 T851

aluminum plate sheet was developed primarily for elevated temperature

applications requiring guaranteed fracture toughness and improved short

transverse properties, this plate sheet alloy also exhibits good strength

retention and creep resistance at elevated temperatures up to 177 ℃. Fracture

toughness levels of 2121 T851 plate sheet are substantially higher than 2024

T851.

Alloy 2124 T851

plate sheet is recommended for moderately elevated temperature application(

121-177 ℃) requiring better short-transverse ductility and fracture toughness

guarantees than are available with 2024 T851 plate. The primary use is machined

fuselage bulkheads and wing skins in high-performance military

aircraft.

Fracture

toughness is guaranteed for alloy 2124 T851 plate sheet(but not for alloy 2024

T851 plate) and shows more consistent values in different test directions than

2024 T851.

The fatigue

properties of alloy 2124 T851 are similar to those of 2024-T851.

Alloy 2124 T851

resistance to atmospheric corrosion is comparable to that of conventionally

fabricated 2024 T851. Test conducted on numerous lots of 2124 T851 show good

resistance to stress corrosion cracking, particularly in the short-transverse

direction. In 20 years of service there are no reported incidents of SCC

failures.

Alloy 2124 T851

aluminum plate sheet has excellent exfoliation corrosion resistance.

Alloy:

2124

Temper: O, T4, T3,T351,T42,

T8,T851,T62

Stretching capacity:

300000m2, supposed width is 2000mm, then the maximum thickness is

150mm.

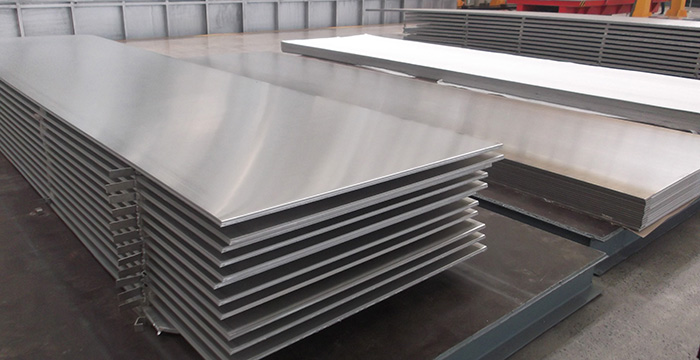

Thickness:

1.0mm--300mm

With:

500mm--3000mm

Length:

1000mm--12000mm

Surface: Mill finish, Bright

finish, paper interleaved, one side film, both sides film.

Chemical Properties

Chemical Properties

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Ni | Zn | Ti | Ga | V | Others |

Aluminium min. |

|

| Each | Total | |||||||||||||

| 2124 | 0.2 | 0.3 | 3.8-4.9 | 0.3-0.9 | 1.2-1.8 | 0.1 | - | 0.25 | 0.15 | - | - | 0.05 | 0.15 | Remainder |