Precision Aluminum Plate

Our concept of precision

Precision is – the accurate,

precise general measurements such as thickness tolerance, flatness, parallelism

and surface roughness, as well as, the focus on the systematic, interior values

such as the physical, metallurgical and technological properties. The result is

a reproducible maximum internal and external, maximum precision for each plate

and each cut.

Aluminium ingots made from

especially developed materials based on our experience undergoes a final

specific in-house heat treatment. Bypassing the conventional rolling process,

our slabs are divided into plates on special saws. The sawing process is so

designed that no stresses are induced into the material. The result are plates

with extreme low-tension and precision-milled surfaces, very fine-grained,

homogeneous micro structure and high strength values.

|

|

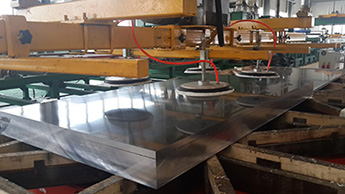

On stable portal milling machines with more than 2 m wide milling heads we generate precision accuracy and the unique surface characteristic for our Precision Aluminum Plates. Each precision plate is inspected in respect of thickness, flatness, surface roughness and finally PVC- coated for surface protection.

The available range

of Precision Aluminum Plates covers all areas of application where

precision in combination with higher strength values are required, such as

construction of jigs & fixtures, all kind of gauges, all kind of table,

indexing and transfer plates, special purpose machines and all parts that

justify the term “precision part”.

1,AMP5083-Aluminum Precision Milled Plate

(1)Product Description

Specific Notes:

*two

surfaces precision milled

*excellent flatness

*stress relieved

*elevated strength

*very homogeneous

*very good corrosion resistance

(2)Typical Fields of Applications

*components requiring a lot of machining

*all

kinds of side and back boards

*all

kinds of base and table plates

*transfer- and indexing plates

*components requiring high strength values combined with

very low residual stresses

*all

kind of gauges

*displays for screens

(3)Technical data sheet

(3)Technical data sheet

| Alloy´s Characteristics | |||

| Alloy | AMP5083 | ||

| Type of Alloy | non heat treatable | ||

| Temper | homogenized and stress relieved | ||

| Surface | two surfaces precision milled, roughness ≤Ra 0.4 µm, foiled on both sides | ||

| Mechanical Properties | Typical values | ||

| Yield strength Rp0,2 | [MPa] | 110 – 140 | |

| Ultimate tensile strength Rm | [MPa] | 220 – 300 | |

| Elongation A5 | [%] | 10 – 20 | |

| Hardness HBW | [HB] | 70 – 85 | |

| Physical Properties | Typical values | ||

| Density | [g/cm³] | 2.66 | |

| Module of elasticity | [GPa] | 70 | |

| Electrical conductivity | [m/Ω · mm²] | 16 – 19 | |

| Coefficient of thermal expansion | [K-1 · 10-6] | 24.2 | |

| Thermal conductivity | [W/m · K] | 110 – 140 | |

| Processing Characteristics | |||

| Dimensional stability | Very Good | ||

| Machinability | Very Good | ||

| Erodability | Very Good | ||

| Weldability (/ TIG / MIG / ERW/EBW) | Good/ Good/ Good/Very Good | ||

| Corrosion resistance ( stress cracking/seawater / weather) | Normal/ Good/Very Good | ||

| Highest Use temperatures ( long term/Occasional) | 100/180℃ | ||

| Polishability | Very Good | ||

| Oxidability(Technical/Decorative) | Good/Not application | ||

| Contact with food (according to EN 602) | Good | ||

| Tolerances | |||

| Thickness [mm] | Flatness [mm] | Roughness | Width & Length [mm] |

| +/-0.12mm |

≤ 0.35mm/m(T≤15mm) ≤ 0.13mm/m(T>15mm) |

≤ 0.4 µm | 0/+6mm & 0/+10mm |

| Standard Stock Sizes | |||

| Plate Dimension [mm] | 1,470 × 3,000 | in thickness of 6mm – 250 mm | |

| Max Width:2500mm | 2,500 × 3,000 | Max Length:6000mm | |

|

|

2,AMP5052-Aluminum Precision Milled Plate

1)Product Description

Specific Notes:

*two

surfaces precision milled

*excellent flatness

*stress relieved

*elevated strength

*very homogeneous

*very good corrosion resistance

(2)Typical Fields of Application

*Manufacturing device of semi-conductor

*Manufacturing device of liquid crystal

*Manufacturing device of solar panel

*Industrial robot

*Office automation equipment

*Optical instrument

(3)Technical data sheet

| Alloy´s Characteristics | |||

| Alloy | AMP5052 | ||

| Type of Alloy | non heat treatable | ||

| Temper | homogenized and stress relieved | ||

| Surface | two surfaces precision milled, roughness ≤ 0.4 µm, foiled on both sides | ||

| Mechanical Properties | Typical values | ||

| Yield strength Rp0,2 | [MPa] | 60 – 90 | |

| Ultimate tensile strength Rm | [MPa] | 160--220 | |

| Elongation A5 | [%] | 20 – 30 | |

| Hardness HBW | [HB] | 45 – 60 | |

| Physical Properties | Typical values | ||

| Density | [g/cm³] | 2.68 | |

| Module of elasticity | [GPa] | 70 | |

| Electrical conductivity | [m/Ω · mm²] | 19 – 21 | |

| Coefficient of thermal expansion | [K-1 · 10-6] | 23.8 | |

| Thermal conductivity | [W/m · K] | 130 – 150 | |

| Processing Characteristics | |||

| Dimensional stability | Very Good | ||

| Machinability | Good | ||

| Erodability | Very Good | ||

| Weldability (/ TIG / MIG / ERW/EBW) | Good/ Good/ Good/Very Good | ||

| Corrosion resistance ( stress cracking/seawater / weather) | Normal/ Good/Very Good | ||

| Highest Use temperatures ( long term/Occasional) | 100/180℃ | ||

| Polishability | Very Good | ||

| Oxidability(Technical/Decorative) | Good/Not application | ||

| Contact with food (according to EN 602) | Good | ||

| Tolerances | |||

| Thickness [mm] | Flatness [mm] 5) | Roughness | Width & Length [mm] |

| +/-0.12mm |

≤ 0.35mm/m(T≤15mm) ≤ 0.13mm/m(T>15mm) |

≤ 0.4 µm | 0/+6mm & 0/+10mm |

| Standard Stock Sizes | |||

| Plate Dimension [mm] | 1,470 × 3,000 | in thickness of 6mm – 250 mm | |

| Max Width:2500mm | 2,500 × 3,000 | Max Length:6000mm | |