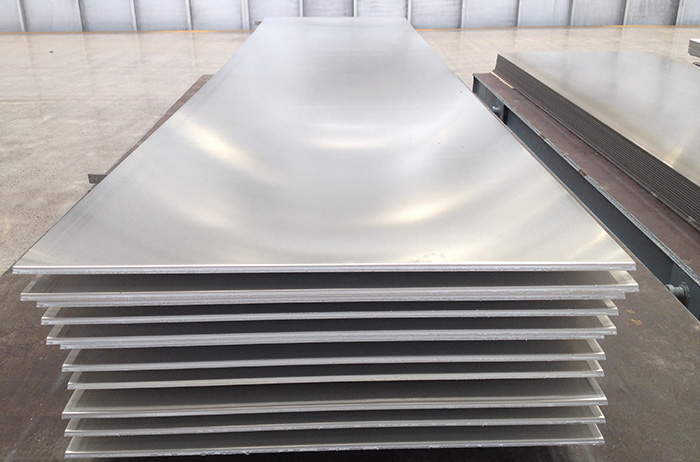

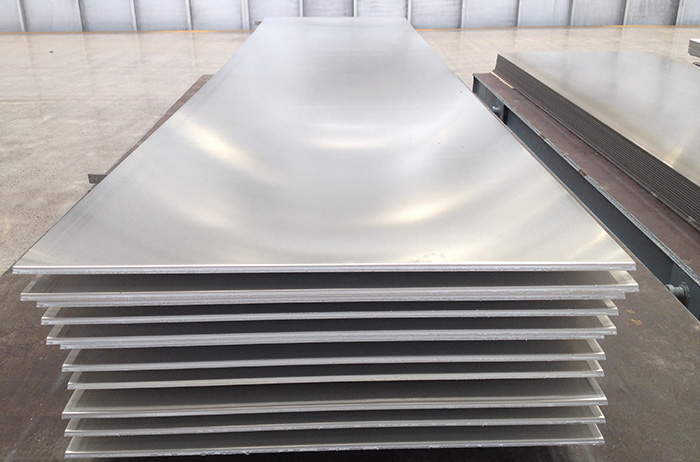

5005 Aluminum Plate Sheet

Alloy

5005 Aluminum Plate Sheet

Alloy 5005 aluminum plate sheet is a medium strength alloy with good resistance to atmospheric corrosion and very good weldability that is highly suitable for decorative anodising. Please note that alloy 5005 aluminum plate sheet is suitable for anodizing, streaks can occur, if the finish you are seeking is critical please specify “special anodising quality” at time of order.

Alloy 5005 aluminum plate sheet is a medium strength alloy with good resistance to atmospheric corrosion and very good weldability that is highly suitable for decorative anodising. Please note that alloy 5005 aluminum plate sheet is suitable for anodizing, streaks can occur, if the finish you are seeking is critical please specify “special anodising quality” at time of order.

Alloy 5005

aluminum plate sheet is a non-heat-treatable 0.8% magnesium alloy commonly

available in flat rolled coil, sheet and plate from a wide range of producing

mills. The 5000-series magnesium alloys have a high strengths because of the

magnesium addition; 5005 has only a very small addition of magnesium so is the

least

strength of these series of

alloys. The alloy is hardenable to a HWALUficant degree by cold working,

enabling a series of “H” tempers but again these do not achieve the

high strengths of corresponding tempers in other alloys such as 5052 or

5083.

The most common

tempers for 5005 aluminum plate sheet are:

H34 stabilised - A low

temperature thermal treatment or heat introduced during manufacture which

stabilised the mechanical properties and relieves residual internal stress, plus

usually improves ductility

The alloy is

also produced as stranded conductor, drawn seamless tube, wire and bar,

available on indent from Atlas.

Corrosion

Resistance

Excellent in a wide range of

atmospheric environments, in architectural applications. The magnesium content

is low enough that it does not suffer from the stress corrosion cracking that

can affect alloys with more than about 3½% Mg, such as

5083.

Heat

Treatment

Alloy 5005 aluminum plate

sheet is not hardenable by heat treatment. It can be HWALUficantly hardened by

cold work (eg by cold rolling) and various “H” tempers are produced

– most commonly H32 (¼ Hard) and H34 (½ Hard) – as

well as the soft annealed Temper O condition. The alloy spontaneously

age-softens at room temperature immediately after cold work but will eventually

reach a stable condition; all flat rolled mill products are supplied with stable

properties. This is usually achieved by a stabilisation thermal treatment,

either a low temperature thermal treatment or as a result of heat introduced

during rolling, which results in the H3x tempers. H2x tempers are

more

severely strain hardened and

then partially annealed, again to quickly reach the required stable temper

properties. To soften Alloy 5005 it can be annealed by heating to 345°C,

hold until uniform temperature then cool; the rate of cooling is not

important.

Anodising

All aluminium alloys can be

anodised to improve corrosion resistance, but decorative anodising is only

carried out on a few alloys. The most commonly decoratively anodised

non-heat-treatable alloy is 5005. It is produced as a special “anodising

quality” (AQ) but Atlas does not stock this product. It is most common and

usually successful for general purpose quality (non-AQ) to be anodised; this can

however result in some visually inconsistent anodising outcomes and in severe

cases in “tiger stripe” appearance. It is always recommended that

anodising performance be tested by trialling a piece from a batch of

sheet.

AQ sheets can be sourced on

indent if required for critical applications.

When anodised, film on 5005

is clearer and lighter than on 3003 and gives better colour match with 6063

architectural extrusions.

Welding

Excellent weldability by all

standard methods; gas, electric and resistance welding. GMAW and GTAW are

preferred and widely used. Filler alloys are usually 4043 although other alloys

are possible. Welding of strain hardened tempers will reduce strengths in the

heat affected zones.

Machining

Machinability is poor, with

the harder tempers such as H34 and above being somewhat easier to

machine.

Applications

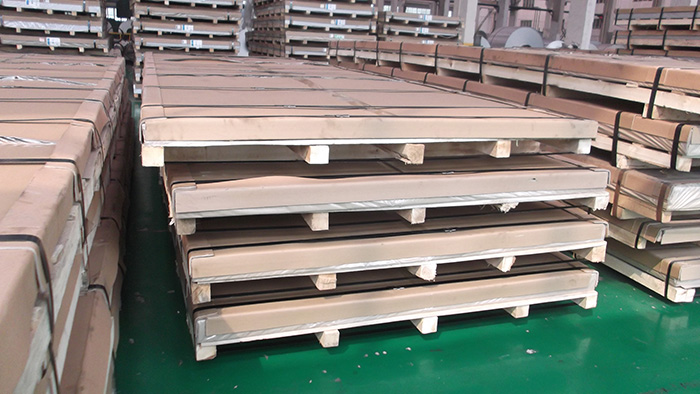

Alloy 5005 aluminum plate sheet is typically used for:

Alloy 5005 aluminum plate sheet is typically used for:

Buildings-roofing, cladding,

corrugated sheet.

Signage, Road signs& name

plates.

Food&chemical

equipment

Furniture

Anodised parts

HVAC

Equipment

Packaging

Pipe and Tube

Can Bodies

Alloy:

5005

Temper: O, H111, H112,

H12,H14, H16, H18, H32, H34, H36, H38

Thickness:

0.2mm--200mm

With:

500mm--2800mm

Length:

1000mm--12000mm

Surface: Mill finish, Bright

finish, paper interleaved, one side film, both sides film.

Chemical Properties

Chemical Properties

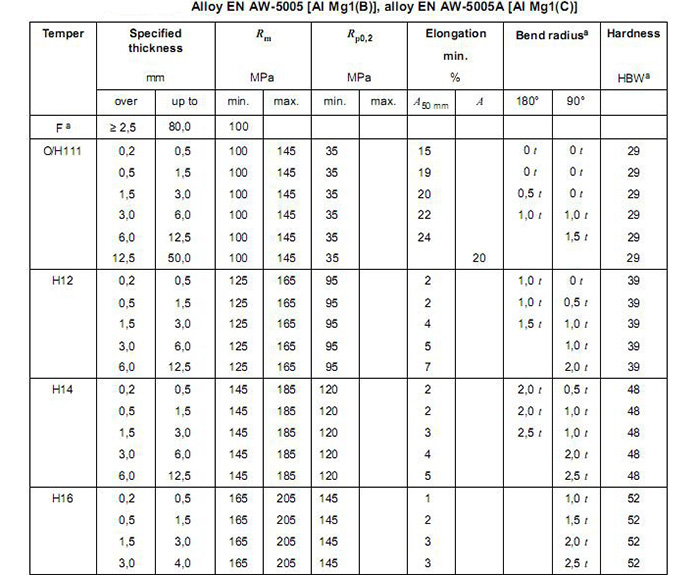

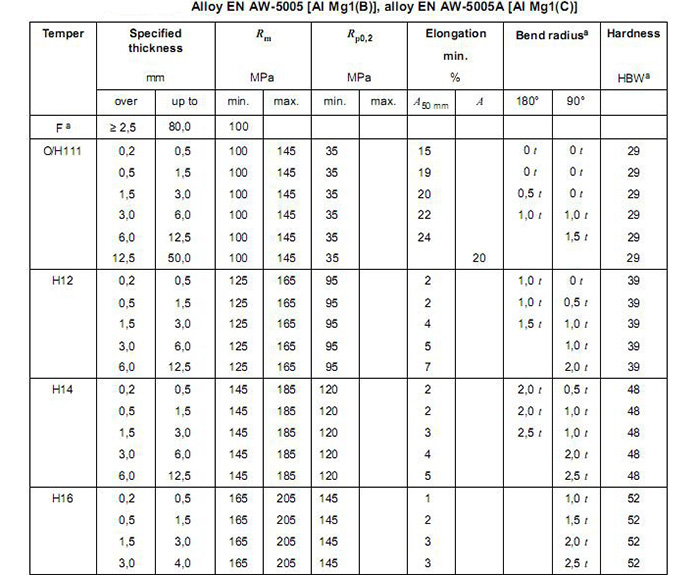

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Ni | Zn | Ti | Ga | V | Others |

Aluminium min. |

|

| Each | Total | |||||||||||||

| 5005 | 0.3 | 0.7 | 0.2 | 0.2 | 0.5-1.1 | 0.1 | - | 0.25 | - | - | - | 0.05 | 0.15 | Remainder |