Automotive Aluminum Plate

Automotive aluminum plate

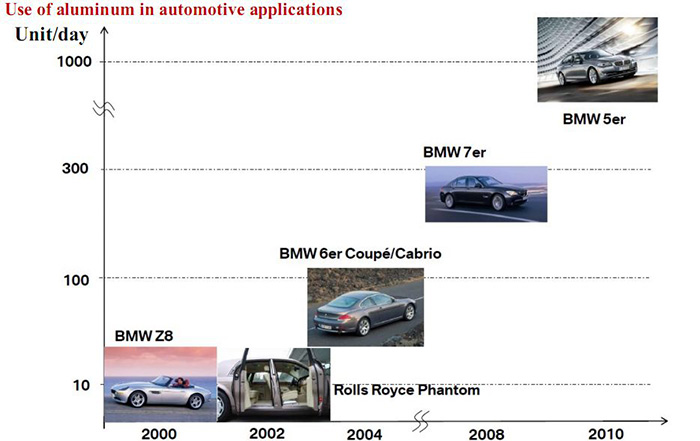

Back to the time in 1910, aluminum plate has already been used in public transportations. After decades’ development, nowadays, most of the bodies of fuel-tank trucks, semi-trailers and trailers are made of aluminum plate products. In the meantime, there is an increment in the use of aluminum plate products in passenger cars, so, in the near future aluminum car bodies must occupy the advantage in the market.

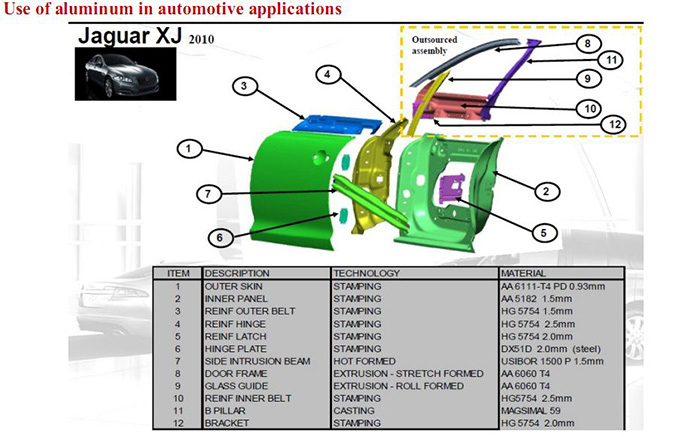

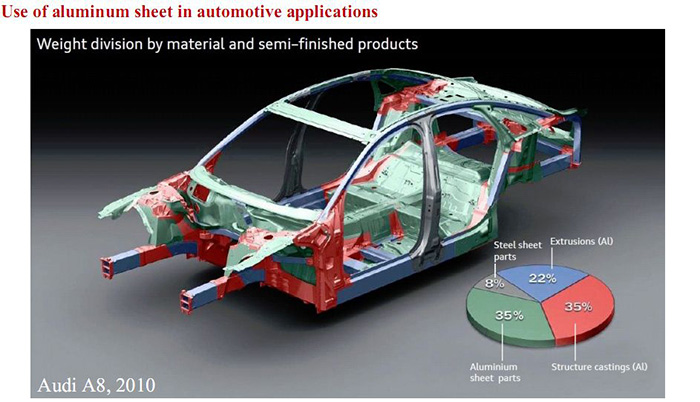

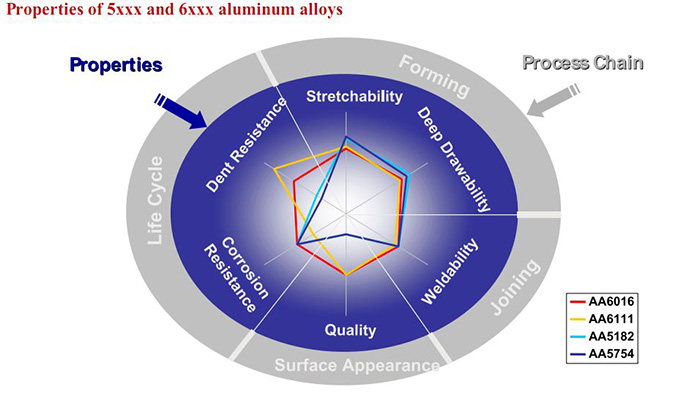

The most commonly used aluminum alloys plate in automotive industry: 5083-O, 5182-O, 5754-O, 6014 T6, 6022 T6, 6063 T6, 6111 T4, 6016 T4, 7075 T6, T651.

There are serious advantages for the application of aluminum in autos, such as higher strength-to-weight ratio, higher fuel efficiency, and better formability. As a result, in such a tough period regarding to energy and environmental issues, aluminum plays an essential role in weight lightening, and fuel efficiency increment to ease the energy and environmental problems.

HWALU aluminum is capable of providing

various aluminum plate and profiles for

automotive industries, which can be used in truck chassis, oil tank, passenger car

body panel, body structure and heat exchange system etc.

Classic alloy: 5182, 5083, 6016, 6011, 6N12, 6014,

6181A, 6009, 6005A, 6061, 6082

Product character: good weldability, good formability, superb

bake hardening ability.

| Specifications | ||||

| Alloys (AA) | Temper | Thickness range (mm) | Length range (mm) | Width range (mm) |

|

5182, 5083, 6016, 6011, 6N12, 6014, 6181A, 6009, 6005A, 6061, 6082 |

F and O H111, H112, T4, T6 (For 6061, 6063), T651(Stretched plate) |

6 — 300 | 1000 — 10000 | 500 — 2700 |

| Stretched aluminum plate | |

| Thickness limit | 6 — 70 mm |

| Length limit | 2000 — 10000 mm |

| Chemical composition | ||||||

| Alloy (%) | 5182 | 5083 | 6181A | 6005A | 6061 | 6082 |

| Si | 0.20 | 0.40 | 0.8~1.2 | 0.50~0.9 | 0.40— 0.80 | 0.7~1.3 |

| Fe | 0.35 | 0.40 | 0.45 | 0.35 | 0.70 | 0.50 |

| Cu | 0.15 | 0.10 | 0.10 | 0.30 | 0.15— 0.40 | 0.10 |

| Mn | 0.20~0.50 | 0.40— 1.0 | 0.15 | 0.50 | 0.15 | 0.40~1.0 |

| Mg | 4.0~5.0 | 4.0— 4.9 | 0.6~1.0 | 0.40~0.7 | 0.8— 1.2 | 0.6~1.2 |

| Cr | 0.10 | 0.05— 0.25 | 0.10 | 0.30 | 0.04— 0.35 | 0.25 |

| Ni | — | — | — | — | — | — |

| Zn | 0.25 | 0.25 | 0.20 | 0.20 | 0.25 | 0.20 |

| Ti | 0.10 | 0.15 | 0.10 | 0.10 | 0.15 | 0.10 |

| Each (Others) | 0.05 | 0.05 | 0.05 | 0.05 | 0.05 | 0.05 |

| Total (Others) | 0.15 | 0.10 | 0.10 | 0.15 | 0.15 | 0.15 |

| Al | Remaining | Remaining | Remaining | Remaining | Remaining | Remaining |

| Single number indicates maximum content. | ||||||

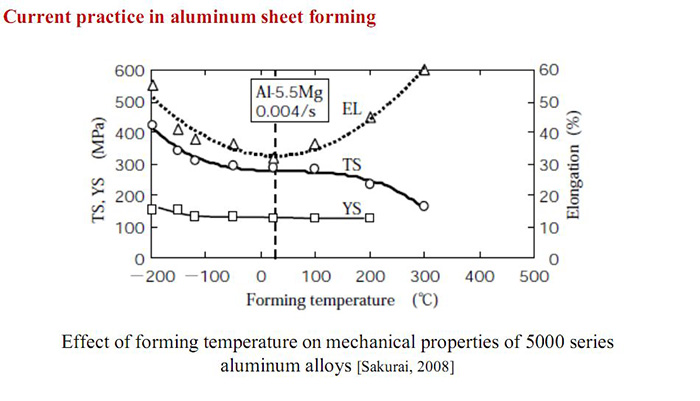

Current Practice in Aluminum Sheet Forming

*Cold forming-- forming at room temperature

*Warm forming-- forming at elevated temperature (<350℃)

The formability of aluminum alloys increases with increasing temperature and decreasing strain rate.

The blank( and sometimes the dies) should be heated.

More complex tools are required and insulation is necessary if the dies are heated.

Cycle time is longer than cold forming due to heating process.

Lubricants that perform well at elevated temperatures should be used.

Springback is reduced.

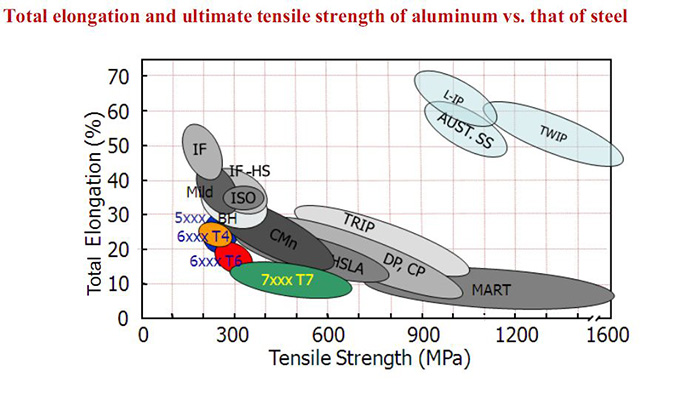

Density, Elastic modulus and anisotropy of aluminum vs. That of steel

* The density of aluminum(2.7g/cm3) is one third of steel(7.85g/cm3), Thus, weight can be reduced.

* Elastic modulus of aluminum(70 Gpa) is one third of steel (210Gpa). As a result, the parts previously designed for steel need to be redesigned to achieve the same stiffness.

| Material | Steel | Aluminum | |||||

| Mild 140/270 |

HSLA 350/450 |

DP 500/800 | MS 1250/1520 | 5754-O | 6060 T6 | 7021 T6 | |

| UTS(Mpa) | 270 | 450 | 800 | 1520 | 130 | 245 | 430 |

* Smaller elastic modulus also results in more springback compensation(assuming the strengths are the same).

* Anisotropy values are lower than steel.

| Packing |

| Aluminum Plate : Aluminum Plates are placed in wooden boxes on wooden skids with runners along the length of the sheet. They are wrapped in HDPE with hardboard on top and bottom of the stack. Hoop iron strapping runs along the length of the sheets. Silica gel packets are put in the boxes for moisture protection.(Aluminum plate) |