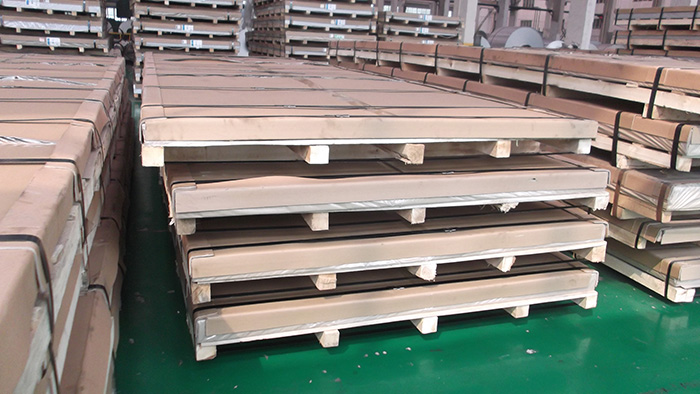

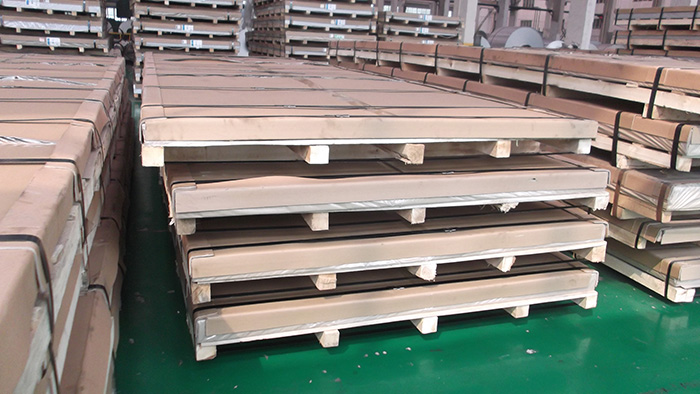

5086 Aluminum Plate Sheet

5086 Aluminum Plate

Sheet

Alloy 5086

aluminum plate sheet have even higher strength than 5052 or 5083 and its

mechanical properties vary HWALUficantly with hardening and temperature. It is

not strengthened by heat treatment; instead, it becomes stronger due to strain

hardening or cold working of the material. This alloy can be readily welded,

retaining most of its mechanical strength. The good results with welding and

good corrosion properties in seawater make Alloy 5086 aluminum plate sheet

extremely popular in marine applications. Alloy 5086 aluminum plate sheet has

been used in vehicle armor plate due to its high strength factor.

.jpg)

.jpg)

Principal Design

Features

This is a non-heat treatable

alloy for strengthening. It has very good corrosion resistance, is easily welded

and does have good strength.

Machinability

No specific data. However the

alloy is machinable by conventional means.

Forming

Forming characteristics are

good for either hot or cold working.

Welding

Weldability of this alloy is

very good by conventional means. When filler rod is required it should be the

same alloy, 5083.

Forging

Forging may be done in the

range of 850 to 750 °F.

Hot

Working

Hot forming, when sever

deformation is required, may be done at 400 °F or higher to 700

°F.

Cold

Working

AL 5083 is readily cold

worked by conventional methods. In the annealed (O temper) condition plate of

0.250" thick can be bent on 1.5 T radius.

Annealing

Annealing may be done at 650

F for sufficient time for thorough heating, followed by air

cooling.

Tempering

Not applicable.

Hardening

Hardening is accomplished by

means of cold working only.

Applications:

Shipyard

Tank cars

Welded and

superstructures

Patrol and work boat

hulls

Armor plate

Commonly used

in the manufacture of unfired, welded pressure vessels, marine, auto aircraft

cryogenics, drilling rigs, TV towers, transportation equipment, and in missile

components.

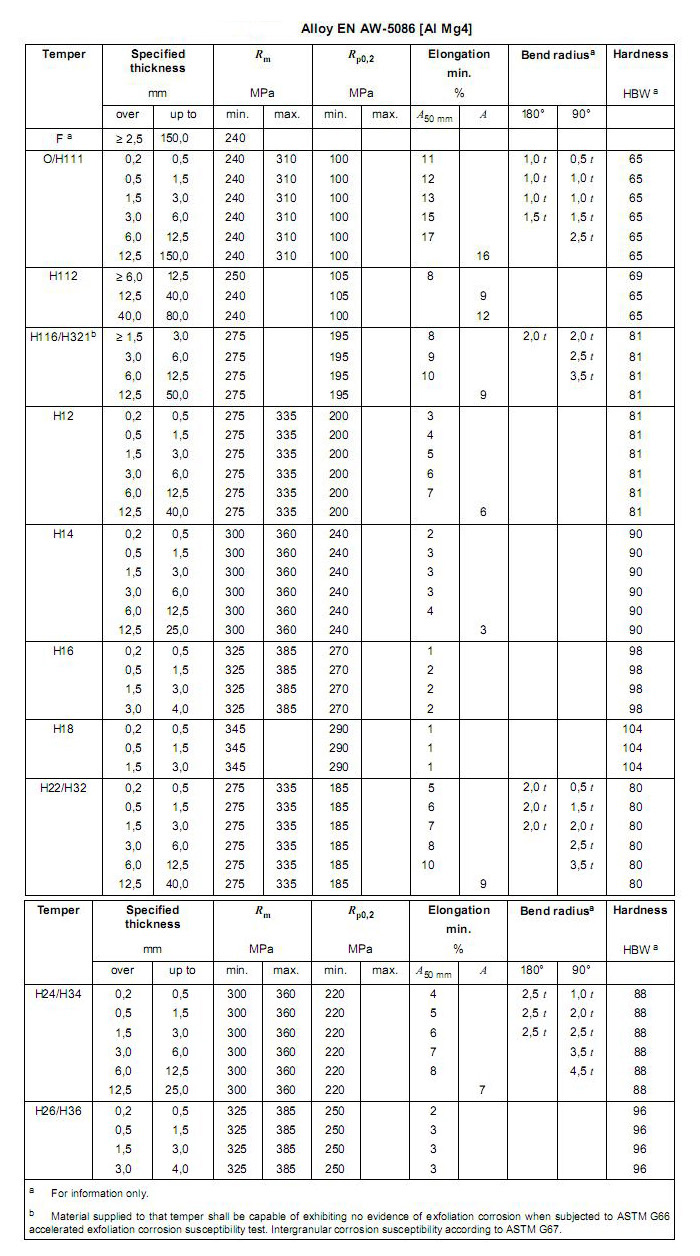

Alloy:

5086

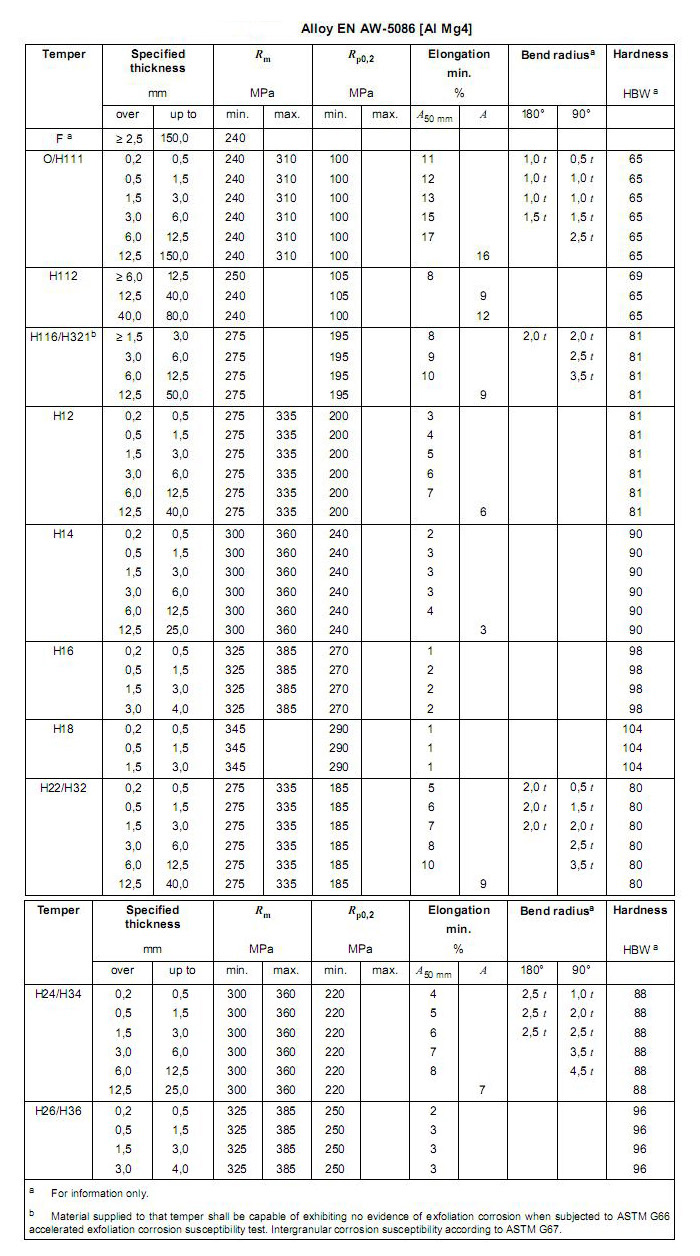

Temper: O, H111, H112, H116,

H321,H12,H14, H16, H18, H32, H34, H36

Thickness:

0.2mm--200mm

With:

500mm--2800mm

Length:

1000mm--12000mm

Surface: Mill finish, Bright

finish, paper interleaved, one side film, both sides film.

Chemical Properties

Chemical Properties

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Ni | Zn | Ti | Ga | V | Others |

Aluminium min. |

|

| Each | Total | |||||||||||||

| 5086 | 0.4 | 0.5 | 0.1 | 0.2-0.7 | 3.5-4.5 | 0.05-0.25 | - | 0.25 | 0.15 | - | - | 0.05 | 0.15 | Remainder |