2024 Aluminum Plate Sheet

2024 Aluminum Plate

Sheet

Alloy 2024

aluminum plate sheet is used in fuselage structurals, wing tension members,

shear webs and ribs and structural areas where stiffness, fatigue performance

and good strength are required. Sheet products usually alclad, are used

extensively in commercial and military aircraft for fuselage skins, wing skins

and engine areas where elevated temperature to 121 ℃ are often encountered.

Alloy 2024

aluminum plate and sheet in the T3 and T4 type tempers are noted for their

excellent toughness at moderately high strength levels.

All alloys of

the 2*** series are susceptible to atmospheric corrosion, especially in

industrial or seacoast atmospheres. These alloys should be protected, at least

on faying surfaces, when exposed to these conditions. Alcaldding these alloys

provides high resistance to atmospheric corrosion. The clad surface is resistant

to corrosive attack and also provides additional cathodic protection to the core

alloy.

Alloy 2014 in

the T351 and T851 tempers has not experienced any in-service problems with

exfoliation. In laboratory tests for exfoliation, alloy 2024 T851 materials was

essentially immune in any test plane.

In the T851

temper, alloy 2024 has very good resistance to SCC. Control of quenching and

artificial aging of 2*** high strength alloys that have been heat treated has

been effective in developing a high resistance to stress-corrosion cracking. In

over 20 years of service experience there have been no reported incidents of SCC

failures in 2024 T351 or 2024 T851 materials.

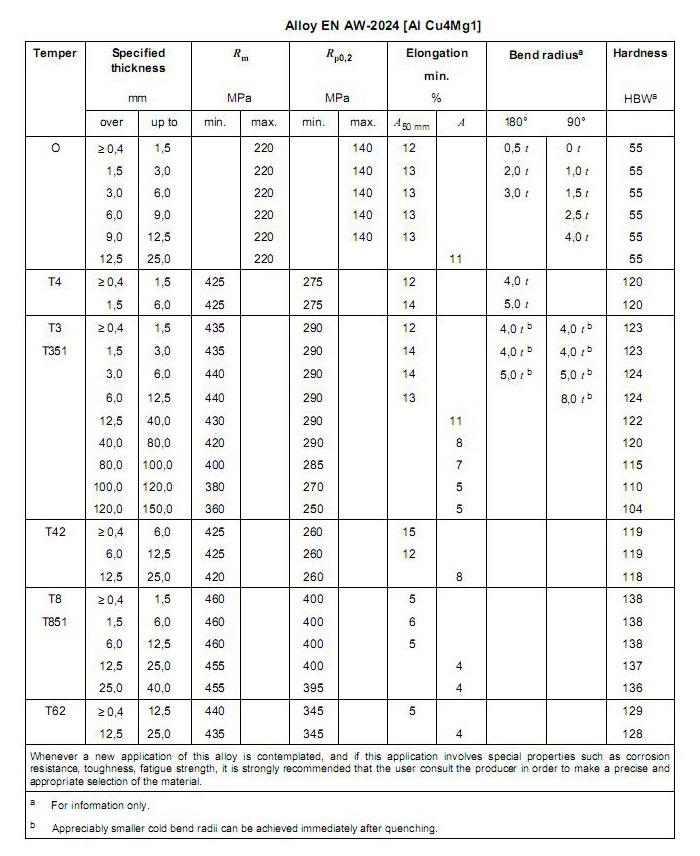

Alloy:

2024

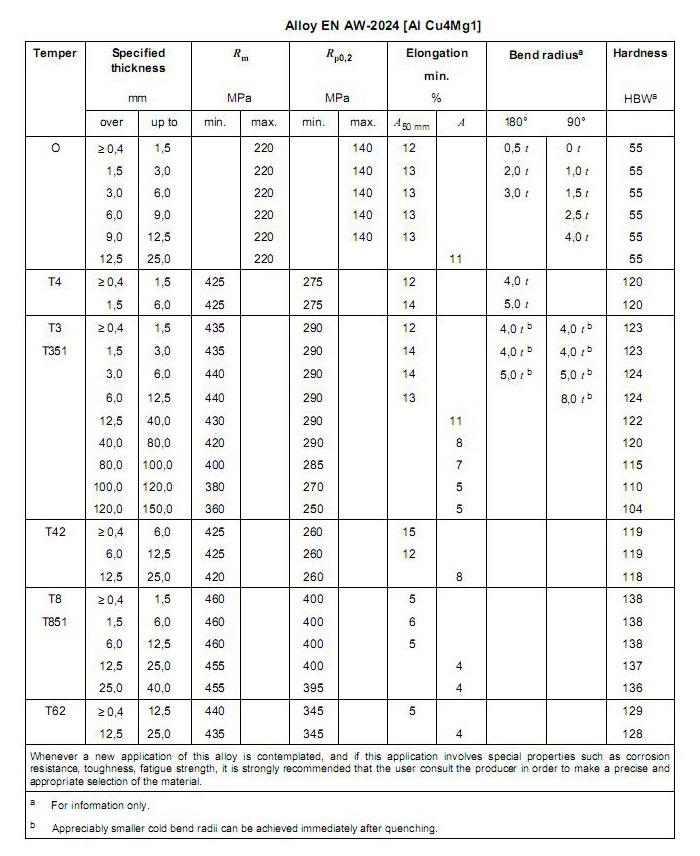

Temper: O, T4, T3,T351,T42,

T8,T851,T62

Stretching capacity:

300000m2, supposed width is 2000mm, then the maximum thickness is

150mm.

Thickness:

1.0mm--300mm

With:

500mm--3000mm

Length:

1000mm--12000mm

Surface: Mill finish, Bright

finish, paper interleaved, one side film, both sides film.

Chemical Properties

Chemical Properties

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Ni | Zn | Ti | Ga | V | Others |

Aluminium min. |

|

| Each | Total | |||||||||||||

| 2024 | 0.5 | 0.5 | 3.8-4.9 | 0.3-0.9 | 1.2-1.8 | 0.10 | - | 0.25 | 0.15 | - | - | 0.05 | 0.15 | Remainder |