7075 Aluminum Plate Sheet

7075 Aluminum Plate

Sheet

HWALU 7075

aluminum plate sheet is one of the highest strength aluminum alloys available.

It has good machinability and an excellent strength to weight ratio, and it is a

popular materials in applications where strength is extremely critical. 7075

aluminum plate sheet is often used for highly stressed parts, and has average

corrosion resistance, improved resistance is normally obtained by cladding

parts. Welding is generally not recommended. 7075 is a heat treatable grade of

aluminum, and sometimes used in place of 2024.

HWALU 7075

aluminum plate sheet have application throughout aircraft and aerospace

structures where a combination of high strength with moderate toughness and

corrosion resistance are required. Typical applications are alclad skin sheet,

structural plate components up to 101.6mm in thickness and general aluminum

aerospace applications.

Alclad 7075 aluminum

plate sheet

Two sides

cladding, nominal cladding thickness is 4% on gauges under 1.57mm, 2.5% on

gauges over 1.57mm. Property values for one side clad materials are

similar.

HWALU 7075

aluminum plate sheet offer moderately good strength toughness relationships and

are the standard of comparision for more recent 7*** series alloy developments.

Alloy 7075 aluminum plate sheet are not offered with guaranteed minimum fracture

toughness values.

Corrosion

resistance

HWALU alloy

7075 aluminum plate sheet has been thoroughly evaluated for corrosion resistance

of atmospheric weathering, stress-corrosion cracking and exfoliation in all

currently available tempers. These values have been used as a standard for

comparision in the development of more recent high strength aerospace alloys.

Within the 7*** series of alloys, resistance to general corrosion attack,

exfoliation improves HWALUficantly in the overage tempers(T7 type) compared with

peak strength temper( T6). Generally, the T76 type temper is considered the

exfoliation resistant temper, while the T73 type temper is considered the SCC

resistant temper. It should be noted that T73 is as resistant to exfoliation as

T76, but at lower strength levels. For applications where good surface

appearance is required or in corrosive environments, alcald 7075 plate sheet are

recommended.

Thermal

treatment

Many heat

treatments and heat treating practices are available to develop optimum

strength, toughness and other desirable characteristics for proper application

of alloy 7075 aluminum plate sheet products.

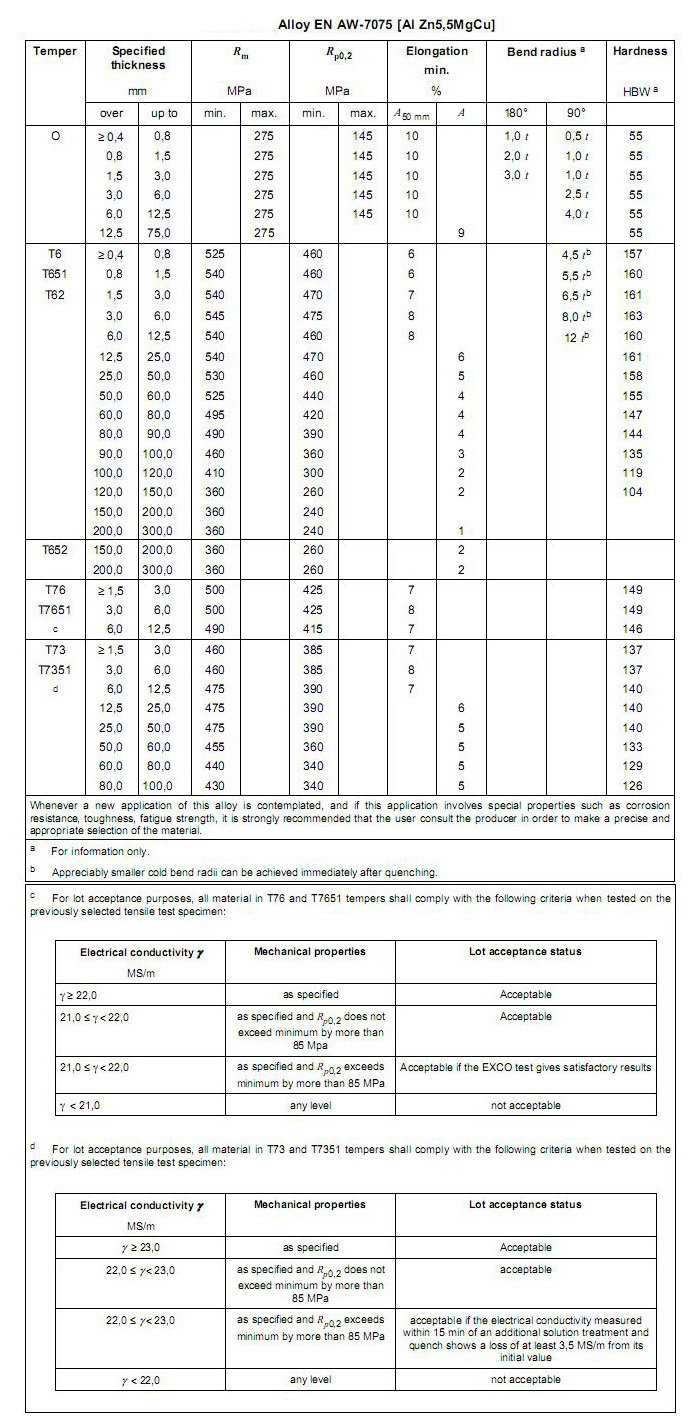

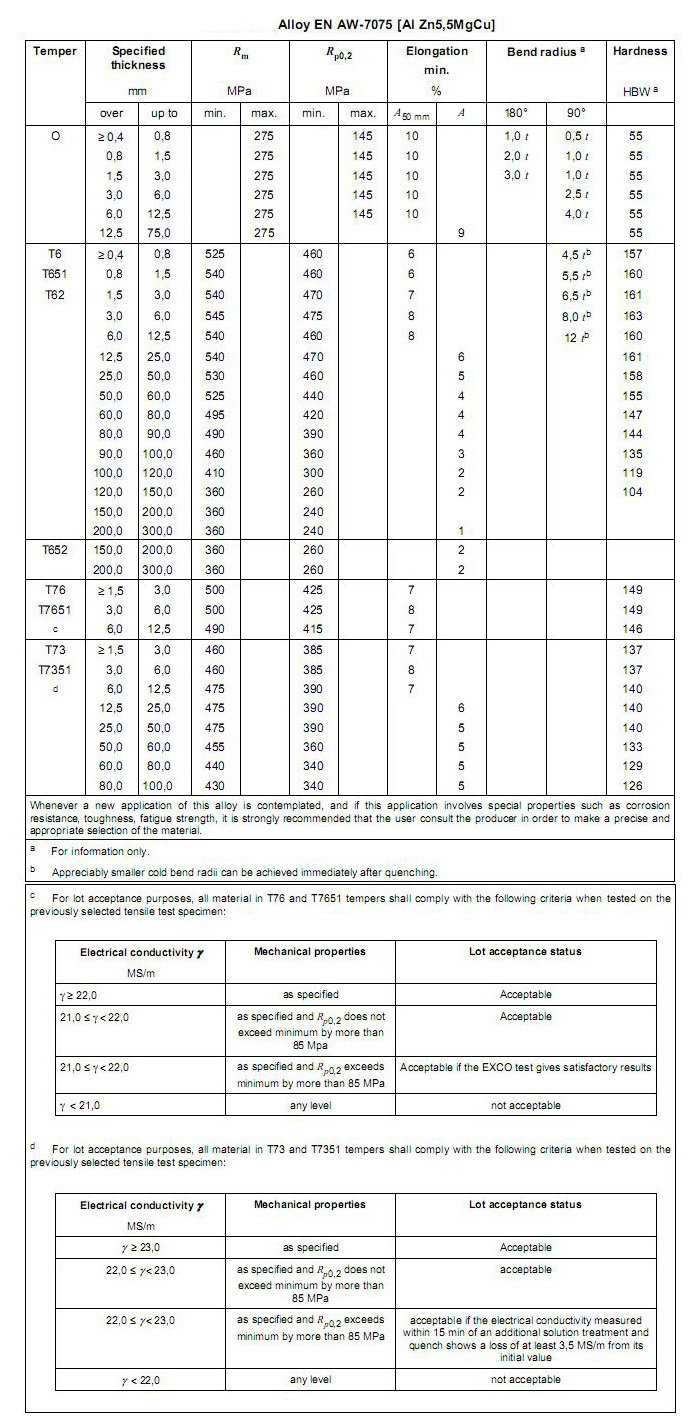

Alloy: 7075

Temper: O, T6, T651, T62,

T652, T76, T7651, T73,T7351

Stretching capacity:

300000m2, supposed width is 2000mm, then the maximum thickness is

150mm.

Thickness:

1.0mm--300mm

With:

500mm--3000mm

Length:

1000mm--12000mm

Surface: Mill finish, Bright

finish, paper interleaved, one side film, both sides film.

Chemical Properties

Chemical Properties

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Ni | Zn | Ti | Ga | V | Others |

Aluminium min. |

|

| Each | Total | |||||||||||||

| 7075 | 0.4 | 0.5 | 1.2-2.0 | 0.3 | 2.1-2.9 | 0.18-0.28 | - | 5.1-6.1 | 0.2 | - | - | 0.05 | 0.15 | Remainder |