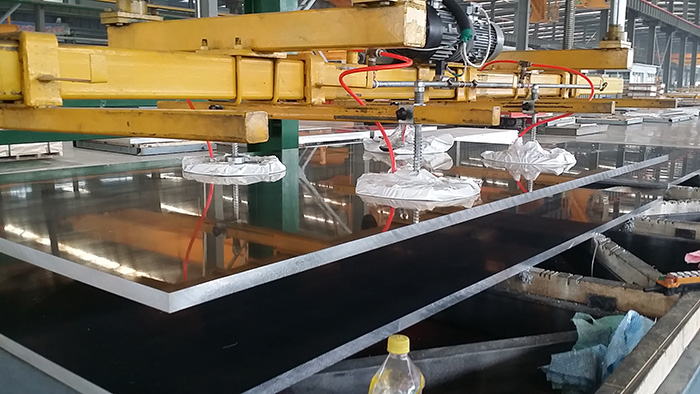

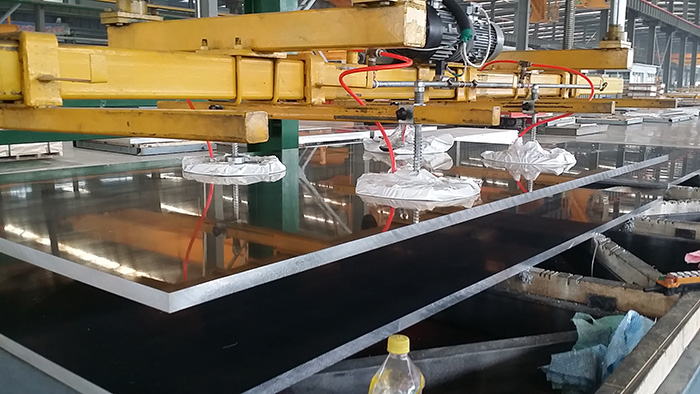

5083 Aluminum Plate Sheet

Alloy 5083 Aluminum Plate

Sheet

Alloy 5083

aluminum plate sheet have higher strength than 5052 plate and has exceptional

thermal conductivity. In the tempered condition, it retains good formability due

to excellent ductility. It is highly suitable for welding and can be hardened by

cold work. Because Alloy 5083 exhibits excellent resistance to general

corrosion, it is used in marine applications. Since Alloy 5083 is capable of

withstanding extremely low temperatures without brittleness or loss of

properties, it is especially suited to the cryogenic market.

Alloy 5083

aluminum plate sheet is a non-heat-treatable 4½% magnesium, 0.15%

chromium, 0.7% manganese alloy commonly available in flat rolled plate from a

range of producing mills. Like all the 5000-series high magnesium alloys 5083

achieves a high strength by cold working,enabling a series of “H”

tempers; 5083 is the

highest strength of any of

these alloys.

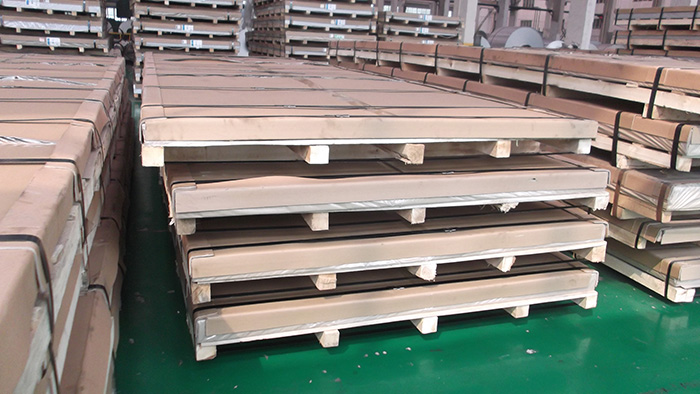

Alloy 5083 aluminum plate

sheet is best known as a plate for ship building.

Corrosion

Resistance

Excellent in a

wide range of atmospheric environments, in food processing and architectural

applications. The principal application for 5083 is marine environments. The

magnesium content is more than 3½% Mg, so this alloy can be susceptible

to stress corrosion cracking, which limits its application temperature to below

65°C and also limits the amount of cold work to ¼ Hard.

Special intergranular

corrosion and exfoliation corrosion tests are carried out to certify 5083 for

marine applications .

Heat

Treatment

Alloy 5083 is

not hardenable by heat treatment. It can be HWALUficantly hardened by cold work

(eg by cold rolling) and various “H”tempers are produced –

most commonly H32 (¼ Hard) or the similar strength marine tempers H116

and H321 – as well as the soft annealed Temper O condition.

The alloy spontaneously

age-softens at room temperature immediately after cold work but will eventually

reach a stable condition; all flat rolled mill products are supplied with stable

properties. This is usually achieved by a stabilisation thermal treatment as the

last operation which results in the H32 or H321 tempers. H112 temper is strain

hardened as the final operation, again to quickly reach the required stable

temper properties. To soften Alloy 5083 it can be annealed by heating to

345°C, hold until uniform temperature then cool; the rate of cooling is not

important.

Welding

Excellent weldability by all

standard electric and resistance methods; gas welding is not recommended. GMAW

and GTAW are preferred and widely used to produce structural welds. When welding

5083 to itself or another alloy in the 5xxx series, the recommended filler metal

is 5183. Other fillers are possible. Welding of strain hardened tempers will

reduce strengths in the heat affected zones.

Machining

Machinability of 5083

aluminum plate sheet is poor due to its high strength.

Typical

Applications

Applications:

LNG ship

construction

Pressure

vessels

Storage tanks

Welded structures (high

strength)

Armor plate

Drilling rigs

Plate for ship building,

unfired welded pressure vessels, rail and other vehicles, various structural

applications that make use of the high strength.

Alloy:

5083

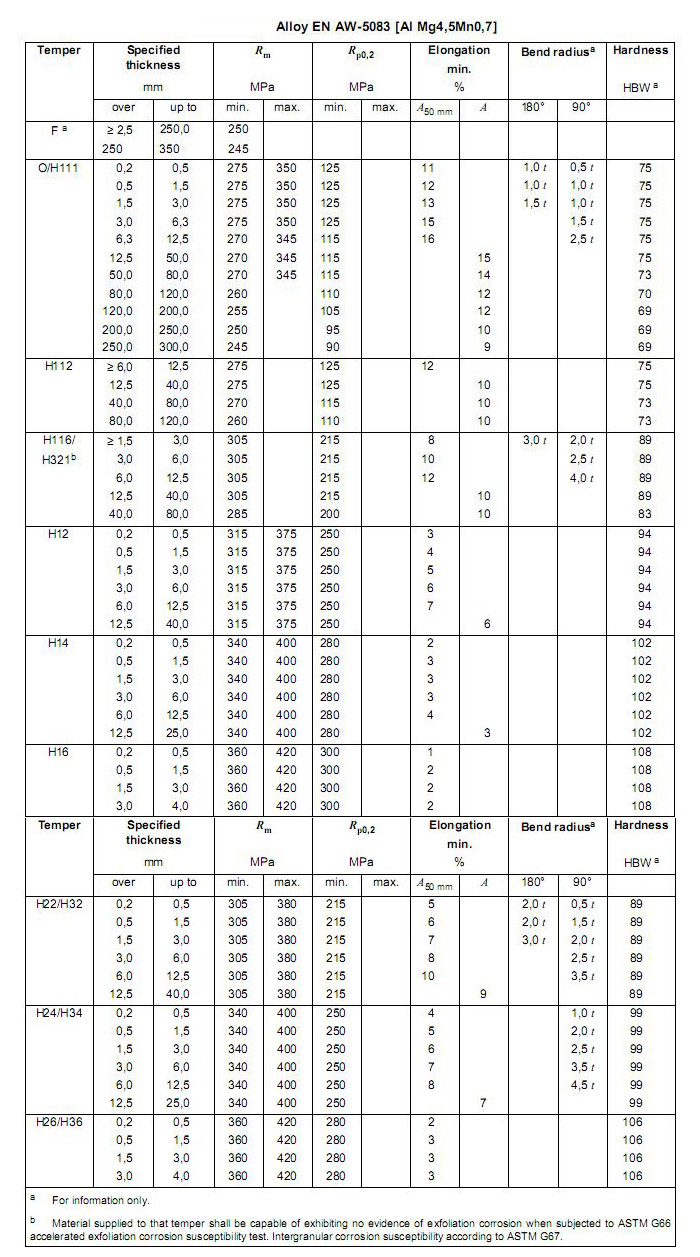

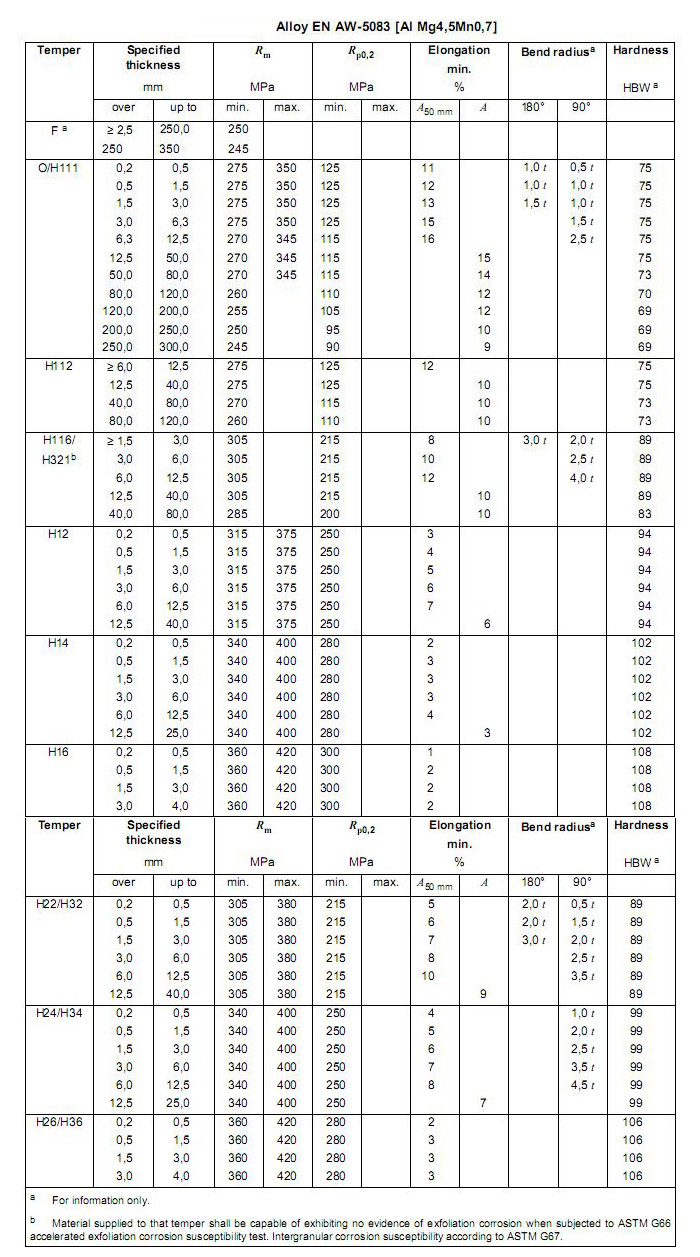

Temper: O, H111, H112, H116,

H321,H12,H14, H16, H18, H32, H34, H36

Thickness:

0.2mm--200mm

With:

500mm--2800mm

Length:

1000mm--12000mm

Surface: Mill finish, Bright

finish, paper interleaved, one side film, both sides film.

Chemical Properties

Chemical Properties

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Ni | Zn | Ti | Ga | V | Others |

Aluminium min. |

|

| Each | Total | |||||||||||||

| 5083 | 0.4 | 0.4 | 0.1 | 0.4-1.0 | 4.0-4.9 | 0.05-0.25 | - | 0.25 | 0.15 | - | - | 0.05 | 0.15 | Remainder |