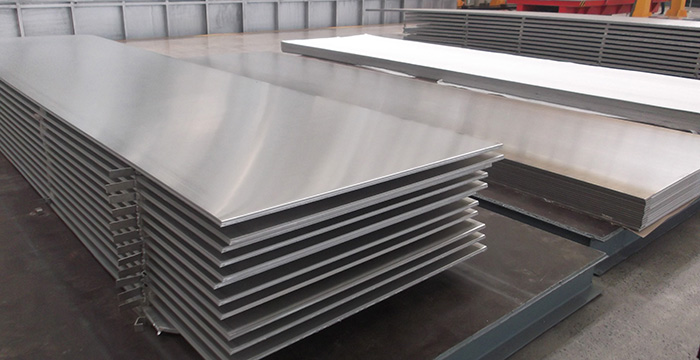

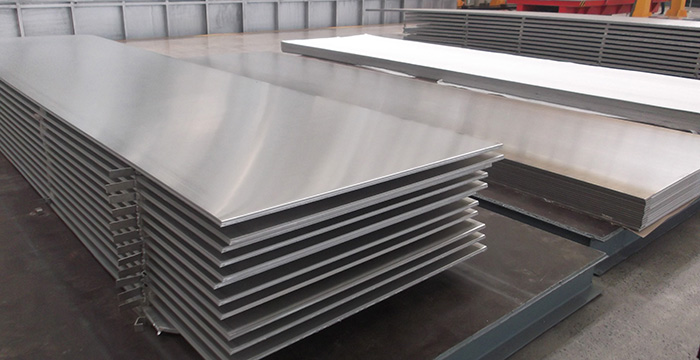

6082 Aluminum Plate Sheet

Alloy 6082 Aluminum Plate

Sheet

Aluminum alloy

6082 plate sheet is a medium strength alloy with excellent corrosion resistance.

It has the highest strength of the

6000 series alloys. Alloy 6082 is known as a structural alloy. In plate form, alloy

6082 aluminum plate sheet i is the alloy most commonly used for machining. As a

relatively new alloy, the higher strength of 6082 has seen it replace 6061 in many

applications. The addition of a large amount of manganese controls the grain

structure which in turn results in a stronger alloy. In the T6 and T651 temper,

alloy 6082 machines well and produces tight coils of swarf when chip breakers are

used.

TEMPER

TYPES

The most common tempers

for 6082 aluminium are :

• T6 - Solution heat

treated and artificially aged

• O - Soft

• T4 - Solution heat

treated and naturaly aged to a substantially stable condition

• T651 - Solution heat

treated, stress relieved by stretching then artificially aged

Alloy 6082 Aluminum Plate

sheet

Alloy 6082 aluminium plate

sheet alloys contain magnesium and silicon as the major alloying

elements.

Strength

Moderately high levels of

strength are obtained through heat treating to the T651 condition, giving higher

strength levels than 5XXX series alloys.

Machinability

6082 aluminium plate alloys

in the T651 condition are easier to machine than 5XXX alloys.

Forming

6082 aluminium plate

alloys can be cold formed in the T651 or T451 temper. Formability is better in

the T451 than the T651 temper and increases with decreasing

thickness.

Corrosion

resistance

6082 aluminium plate alloys,

in the T651/T652/T6 temper, have good corrosion resistance. Unlike some 5XXX

alloys, 6XXX aluminium plate alloys do not suffer degradation in corrosion

resistance after exposure to elevated temperatures.

Welding

6082 aluminium plate alloys

are readily weldable by either GTA-W or GMA-W processes provided that a suitable

filler material is used. Welding reduces the tensile strength to 165-200 MPa in

the heat affected area. In special circumstances, a post weld heat treatment can

be applied to restore some of the lost strength in this area.

6082-T651 and 6061-T651 are

now superseding low-carbon steels in structural applications where the benefits

of lightness, specific stiffness, corrosion resistance and ease of fabrication

can be exploited:

Machined

components

Structural

members

Cargo

containers

Applications

6082 is typically used

in:

Highly stressed

applications

Trusses

Bridges

Cranes

Transport

applications

Ore skips

Beer

barrels

Milk

churns

Alloy:

6082

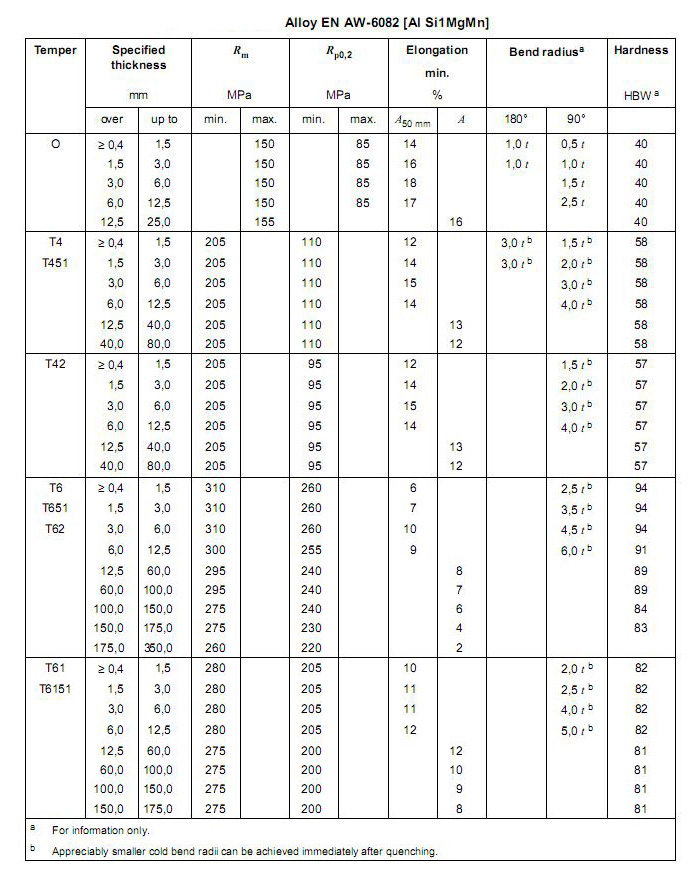

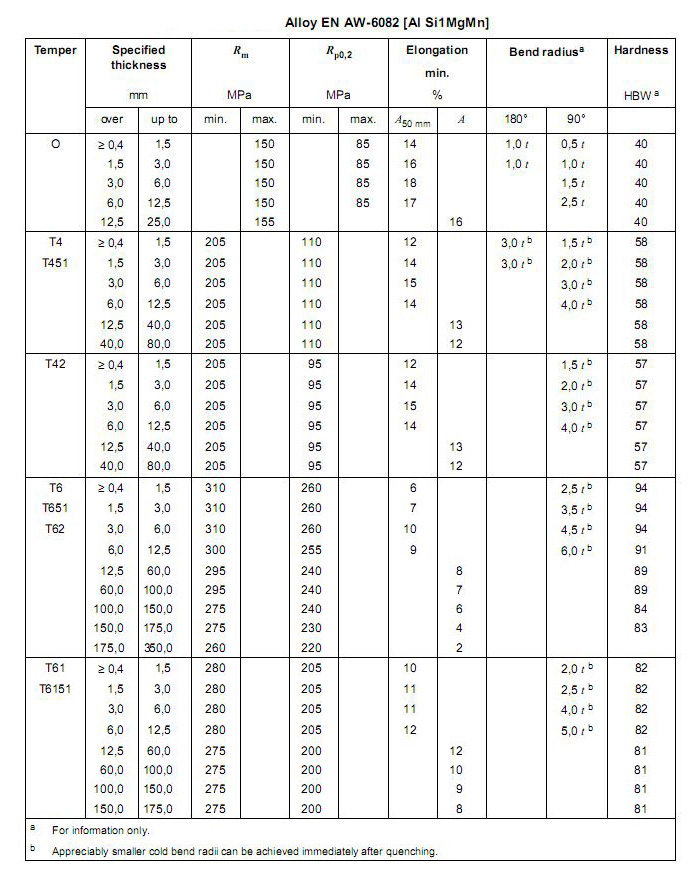

Temper: O, T4, T451, T42,

T6,T651,T62, T61,T6151

Stretching capacity:

300000m2, supposed width is 2000mm, then the maximum thickness is

150mm.

Thickness:

1.0mm--300mm

With:

500mm--3000mm

Length:

1000mm--12000mm

Surface: Mill finish, Bright

finish, paper interleaved, one side film, both sides film.

Chemical Properties

Chemical Properties

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Ni | Zn | Ti | Ga | V | Others |

Aluminium min. |

|

| Each | Total | |||||||||||||

| 6082 | 0.7-1.3 | 0.5 | 0.1 | 0.4-1.0 | 0.6-1.2 | 0.25 | - | 0.2 | 0.1 | - | - | 0.05 | 0.15 | Remainder |