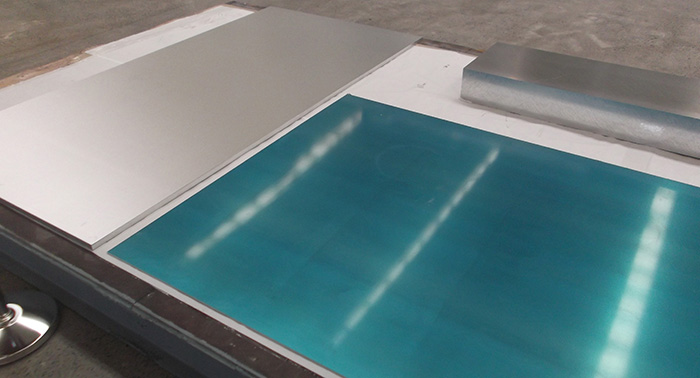

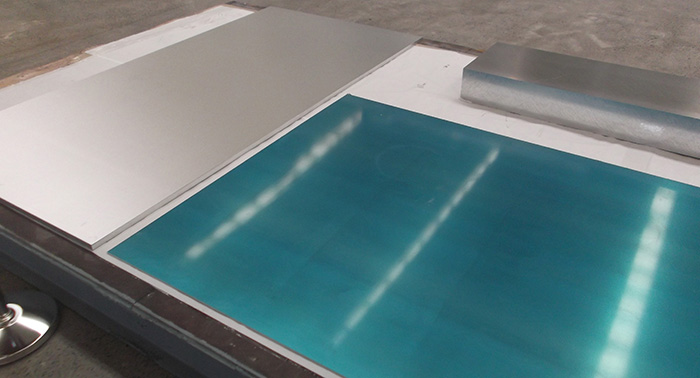

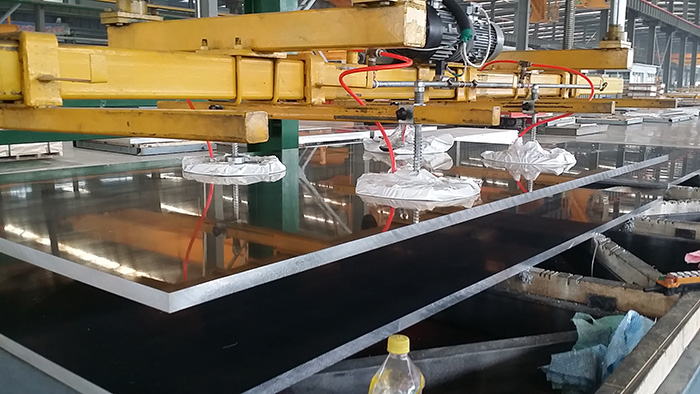

5754 Aluminum Plate Sheet

Alloy 5754 Aluminum

Plate Sheet

Alloy 5754

aluminum plate sheet has excellent corrosion resistance especially to seawater

and industrially polluted atmospheres. It has higher strength than 5251. This

high strength makes 5754 highly suited to marine applications requiring a

combination of strength and resistance to corrosion in sea water. Alloy

5754 aluminum plate sheet is sold basic materials but with high ductility and

elongation, also have very good corrosion resistance, very small tension of the

basic materials. When making tooling, alloy 5754 aluminum plate sheet has

consistent stability in the core of thick plates, have good welding properties

as well.

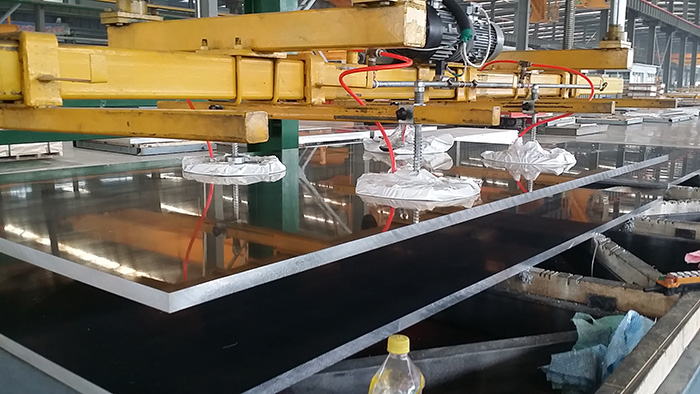

APPLICATIONS

Alloy 5754 aluminum plate

sheet is typically used in :

Tooling

Machines and

machine parts

Pressure

containers

Cans for

beverages and grocery

Tread plate

Shipbuilding

Vehicle

bodies

Marine

applications

Drilling rigs

Transportation

equipment

Fishing industry

equipment

Rivets

Food

processing

Welded chemical

and nuclear structures

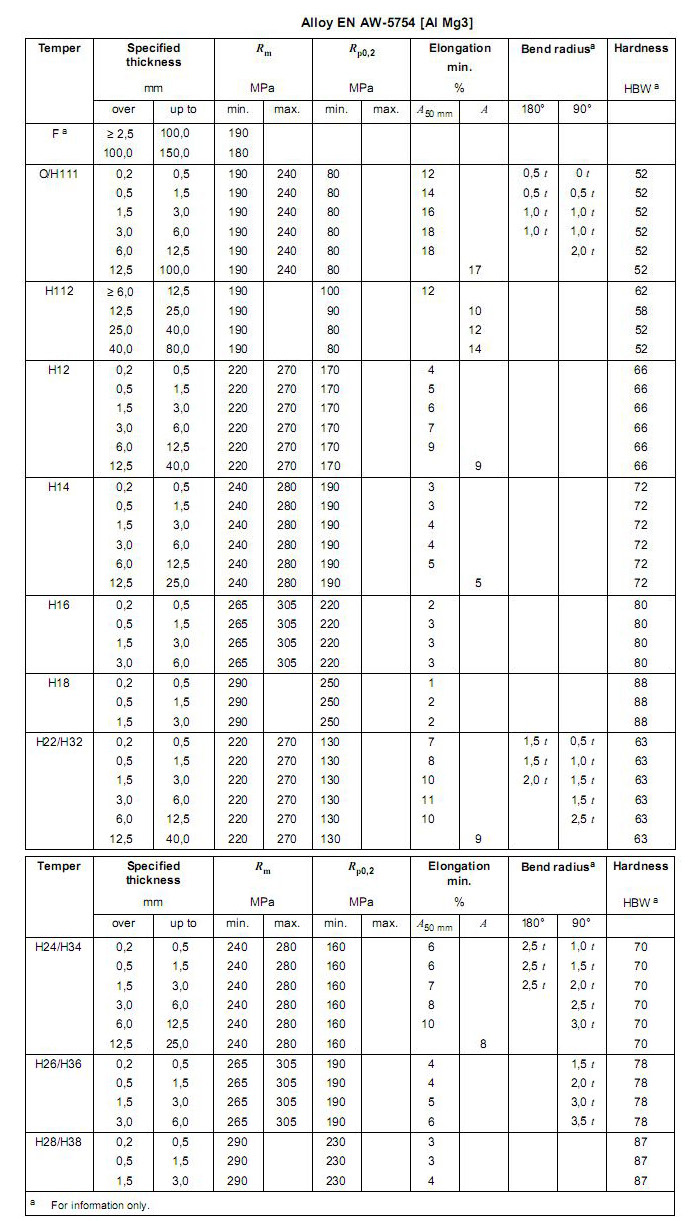

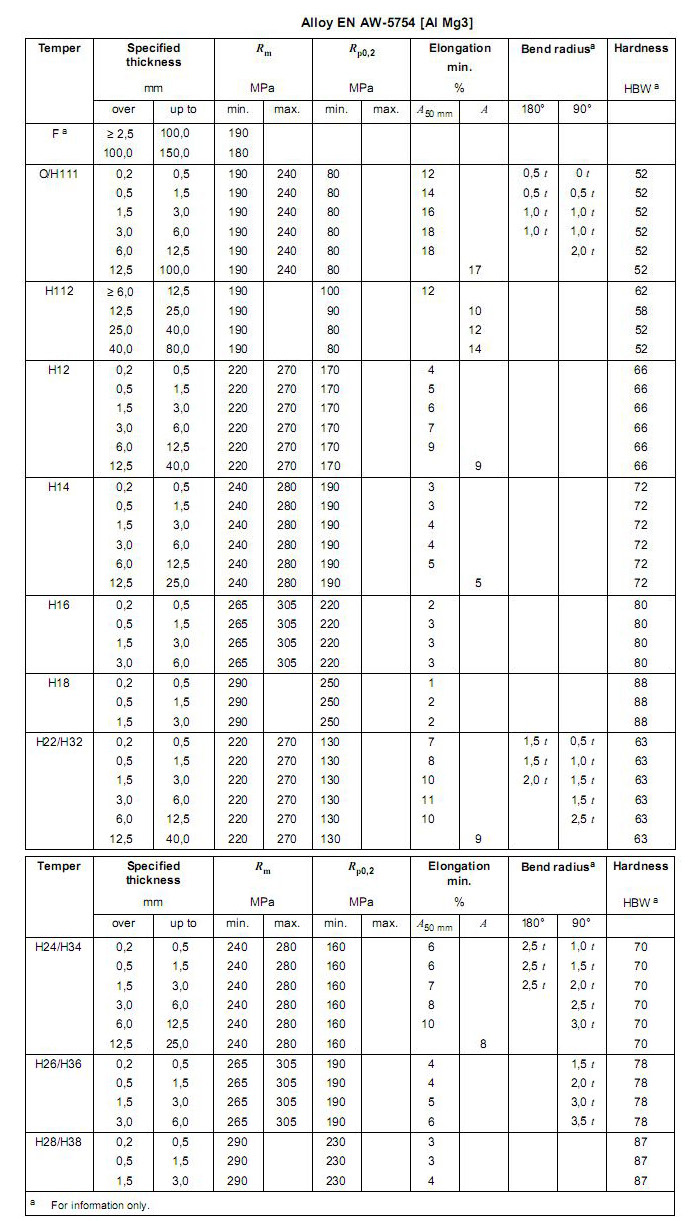

TEMPER

TYPES

The most common tempers for

5754 aluminium are shown below with H114 & H111 being the most common tread

plate temper.

O -

Soft

H111 -

Some work hardening imparted by shaping processes but less than required for H11

temper

H22 -

Work hardened by rolling then annealed to quarter hard

H24 -

Work hardened by rolling then annealed to half hard

H26 -

Work hardened by rolling then annealed to three-quarter hard

Alloy:

5754

Temper: O, H111, H112,

H12,H14, H16, H18, H32, H34, H36, H38

Thickness:

0.2mm--200mm

With:

500mm--2800mm

Length:

1000mm--12000mm

Surface: Mill finish, Bright

finish, paper interleaved, one side film, both sides film.

.jpg)

Chemical Properties

.jpg)

Chemical Properties

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Ni | Zn | Ti | Ga | V | Others |

Aluminium min. |

|

| Each | Total | |||||||||||||

| 5754 | 0.4 | 0.4 | 0.1 | 0.5 | 2.6-3.6 | 0.3 | - | 0.2 | 0.15 | - | - | 0.05 | 0.15 | Remainder |