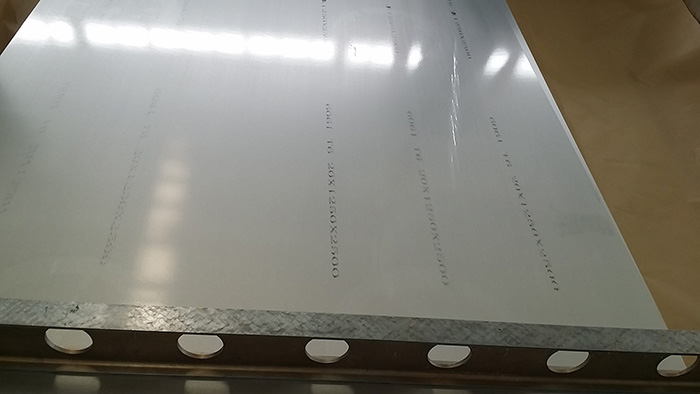

6061 Aluminum Plate Sheet

Alloy 6061 Aluminum

Plate Sheet Product Features:

1.Very good surface and

polished bright surface, Excellent flatness control to the product

;

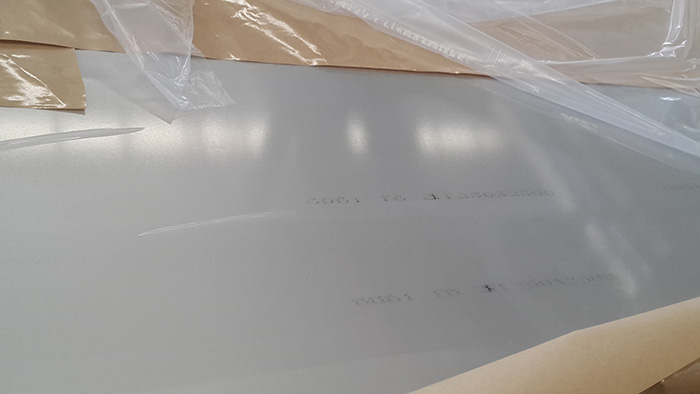

2.Paper interleave /

single side or both sides PE coated for good surface protection

;

3.Excellent anodizing

quality, excellent mechnical property ;

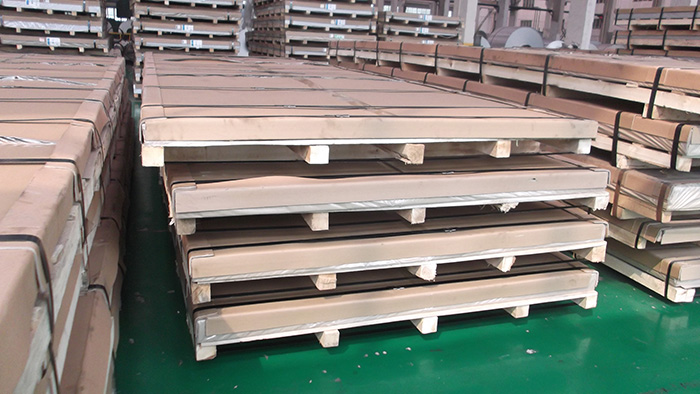

4.Well-protected packing

;

Alloy 6061 aluminum plate sheet is the most commonly specified Aluminum

for general purpose applications. Silicon and Magnsium are the major

alloying element of this heat treatable plate. Commonly used in structural

applications it has good formability, weldability, and corrosion resistance, and

although it might not machine as good as 2024 and 7075, it certainly is used in

many machined part applications that don't require the higher strenght

levels that you get from 7075 and 2024.

Application

HWALU

Aluminum’s alloy 6061 Aluminum plate sheet Material strength,

attractive finish and anodizing are all priorities for aluminum in

electronics. HWALU’s 6061 alloy achieves both and is the preferred

choice in the market for consumer electronics casings. It’s ideal for

larger electronics like notebook computers and televisions. Alternatively,

when strength and mechanical performance is a priority for your product,

6061 Aluminum Plate Sheet also is a outstanding solution for handheld

devices and mobile phones.

Finishes and

Surfaces

Using

authentic material like aluminum in electronic casings gives the consumer a

sense of quality and value that they expect from their product. HWALU

Aluminum’s 6061 alloys are available in a range of esthetically

pleasing mechanical. All are available in a variety of colors, and can be

applied directly to the coil so a finishing step can be eliminated from the

process.

HWALU alloy

6061 T651 wrought tooling plate sheet is produced and certified in

accordance with ASTM B209 and ASME SB209. Its excellent machinability,

weldability, and high strength sets the industry standard for versatility

with a wide range of applications and end uses. Stability and consistency

are integral to the quality of 6061 T651 plate. HWALU’s proprietary

chemistry, casting, and production techniques provide excellent

piece-to-piece stability and consistency. High stability and consistency

reduce warping and movement during sawing and machining.

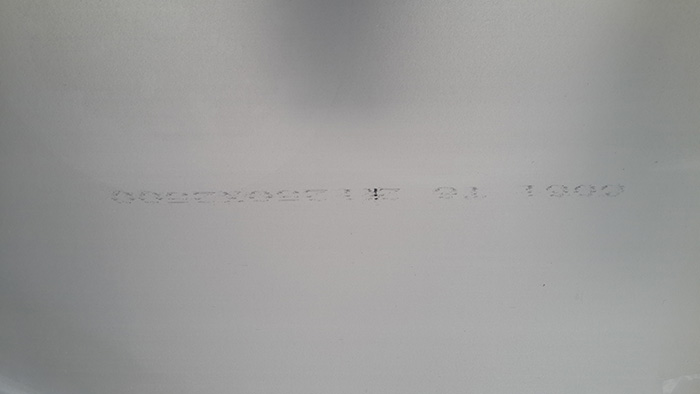

HWALU alloy

6061 T651 wrought tooling plate sheet has satin finish surface, the satin

finish is twice as smooth as plate with coarse, mechanical finishes. This

superior smoothness lets you reduce or eliminate costly surface clean-up

operations.

HWALU 6061 T651 wrought

tooling plate sheet have very good flatness and thickness

tolerances.

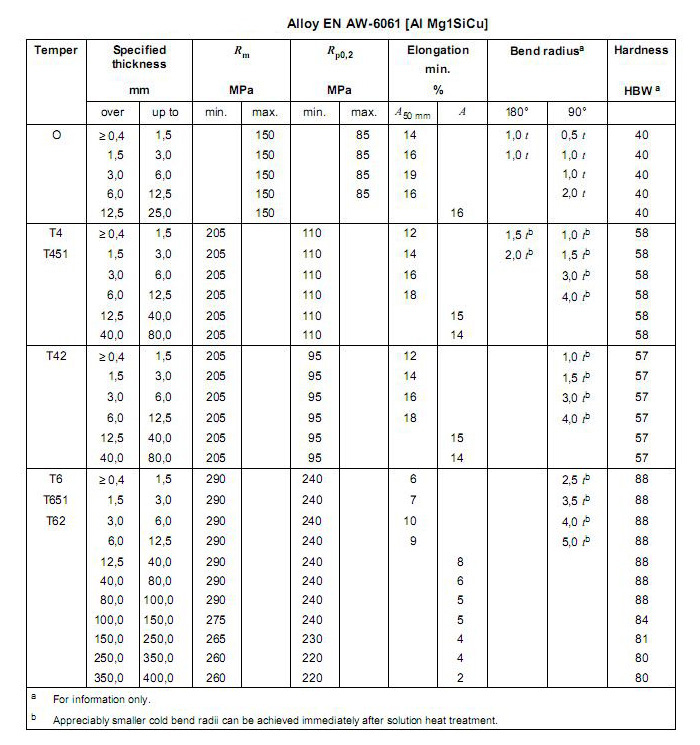

Alloy: 6061

Temper: O, T4, T451, T42,

T6,T651,T62

Stretching capacity:

300000m2, supposed width is 2000mm, then the maximum thickness is

150mm.

Thickness:

1.0mm--300mm

With:

500mm--3000mm

Length:

1000mm--12000mm

Surface: Mill finish,

Bright finish, paper interleaved, one side film, both sides film.

Chemical Properties

Chemical Properties

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Ni | Zn | Ti | Ga | V | Others |

Aluminium min. |

|

| Each | Total | |||||||||||||

| 6061 | 0.4-0.8 | 0.7 | 0.15-0.4 | 0.15 | 0.8-1.2 | 0.04-0.35 | - | 0.25 | 0.15 | - | - | 0.05 | 0.15 | Remainder |