Aluminum Moulding Plate

Mould Aluminum plate Introduction

As the undisputed world leader in aluminum alloy products, HWALU aluminum is uniquely placed in terms of expertise and resources to develop advanced Specialised alloys for aerospace, marine, transport, construction, industrial And engineering applications.

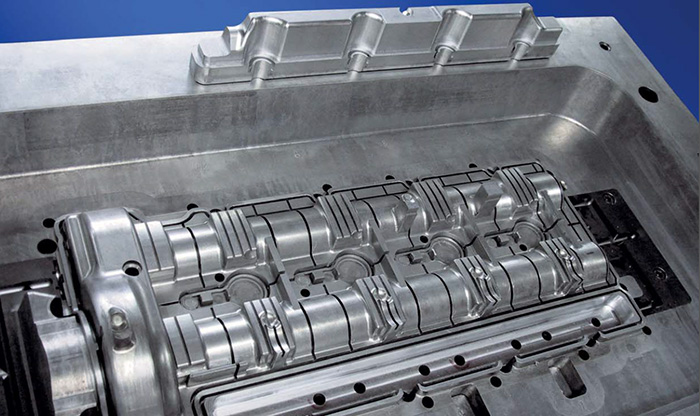

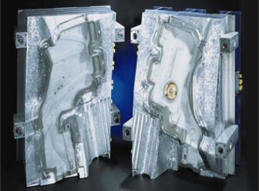

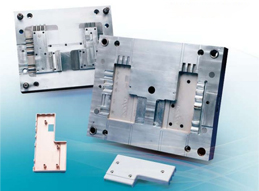

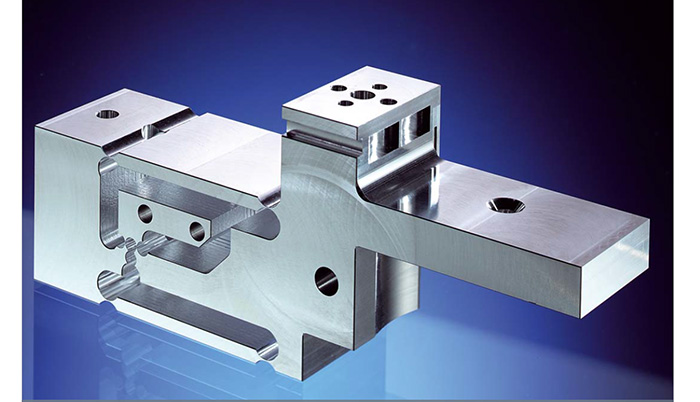

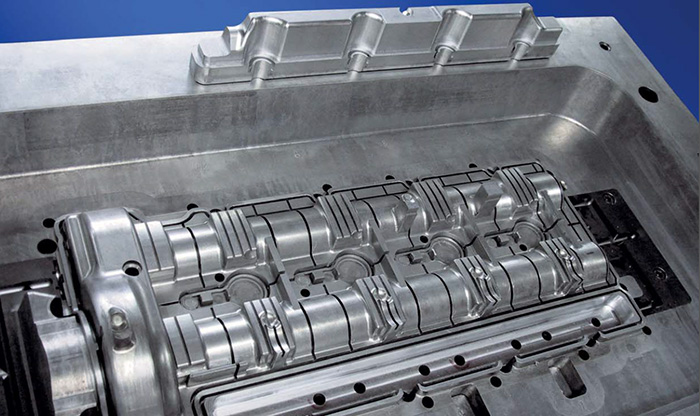

Among the many aluminum plate products and cast forging stock manufactured for export worldwide from the HWALU aluminum mill is a comprehensive portfolio of ultra-high performance alloys optimised for plastic mould tooling plate: the HWALU range. HWALU products are specifically engineered to maximise the operational advantages of using aluminum alloys for todays's moulding technologies, including injection moulding, RIM, structural foam moulding, vacuum forming, blow moulding and rubber moulding.

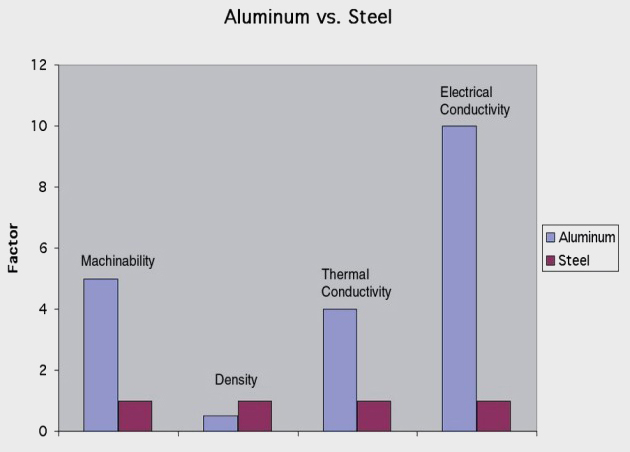

For our clients throughout the world, the business benefits of switching to HWALU are borne out by decades of experience: superior machinability, ease of handling and optimum product quality. Using the same exacting manufacturing standards as employed in supplying aerospace materials, HWALU provides the reassurance of exceptional consistency in terms of quality, reliability and performance. Together with HWALUficant cost savings throughout the production lifecycle from initial machining to eventual disposal, these operational advantages combine to deliver a HWALUficant competitive edge over both steel and generic aluminum alloy alternatives.

Using

HWALU moulds rather than steel substantially reduces production costs in several

ways:

|

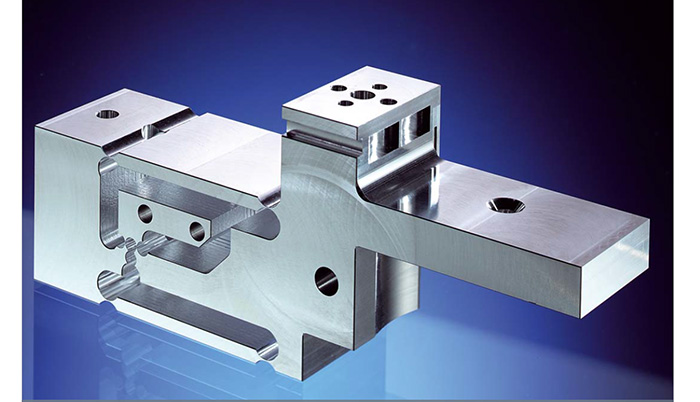

Faster and less costly fabrication

Being

so much easier to machine, HWALU moulds can typically be made in a third of the time

of a steel equivalent, with corresponding savings in fabrication costs. (Ancillary

components such as fittings, pillars and bushes are cost neutral, as conventional

steel components can be used).(Aluminum plate)

|

|

Lower operational costs

HWALU

moulds weigh anything up to 60% less than steel equivalents, so They are easier

to handle and stock, and exert less strain on your process machinery. As well as

extending press life in this way, specifying HWALU also reduces your expenditure

on tooling, machinery set-up, mould maintenance and ongoing

consumables.

|

|

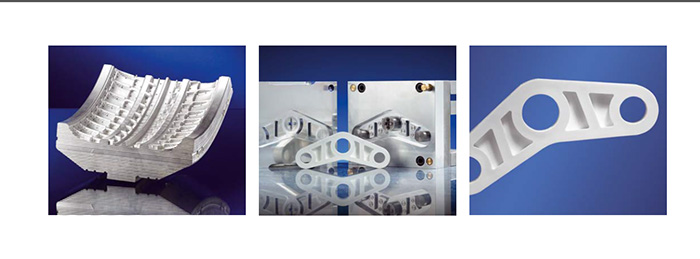

Massive productivity gains

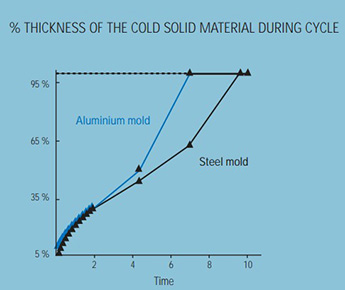

The

thermal conductivity of aluminum plate being many times

higher than steel means that HWALU moulds can cut moulding cycle times - and

therefore increase output - by between 30 and 50%.

|

|

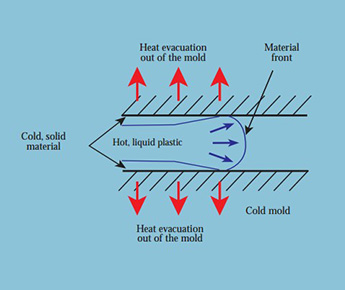

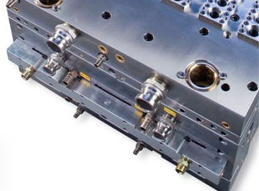

Out standing thermal properties

The

thermal conductivity, or even better thermal diffusivity, of aluminum alloys

characterises the main function of molds: too cool down or heat up.

These

parameters have a direct influence on the duration of the cycle and dimensional

and visual quality of the part.

|

|

Superior machinability and finishing

With

metal removal rates at least four times greater than steel, HWALU has excellent

machinability and is easy to spark and wire erode. High performance surface

finishes are equally simple to achieve with a wide range of processes including

chemical nickel, hard chrome and hard anodising. EDM polishing and photo-etching

deliver more uniform results compared to steel, and the consistently reliable

microstructural integrity of HWALU alloys allows first class mirror finishes to

be obtained for optically critical applications.(Aluminum plate)

|

|

Higher product quality

Superior

thermal conductivity allows an HWALU mould to cool more evenly, minimizing risk

of distortion in the moulded part. Together with lower capital and production

costs, total product consistency and a substantially faster time to market, this

marked quality gain clinches the business case for choosing HWALU.

As

a result of these benefits, one aluminum plate producer estimates

that using aluminum for mold applications can save 30% in cost over steel in

mold manufacturing, increasing to 40% if the reduced part production cycle times

and hence improved productivity are included.

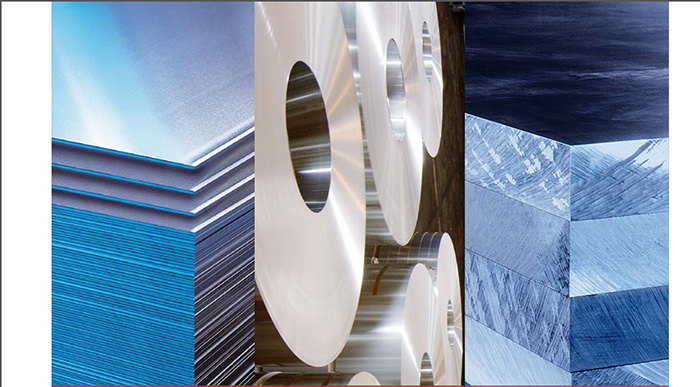

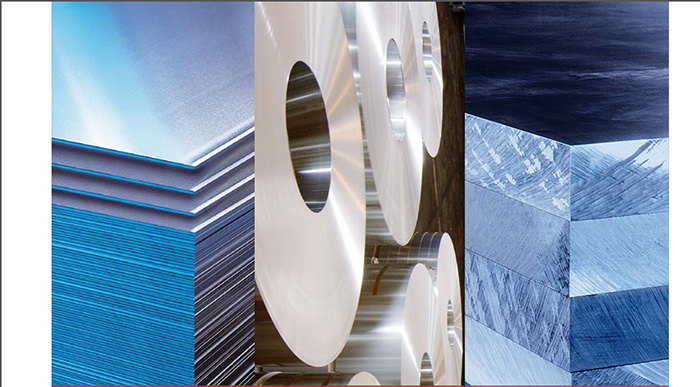

Since

there is a range of different conditions under which tool and mold materials

must operate, different aluminum alloy and temper combinations have evolved to

meet the various needs. Both cast and wrought products are available in a wide

range of thickness, widths, and lengths. Each product type has specific

characteristics that have been tailored to application needs.

|

|

|

|

- Cast plate materials have the following advantages:(Aluminum plate)

- Equiaxed grain structure

- Low residual stress

- Extreme flatness tolerance capability

- Good internal soundness

- Excellent surface finish

-

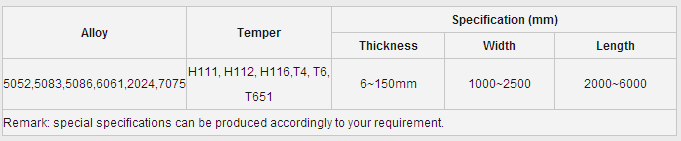

specification

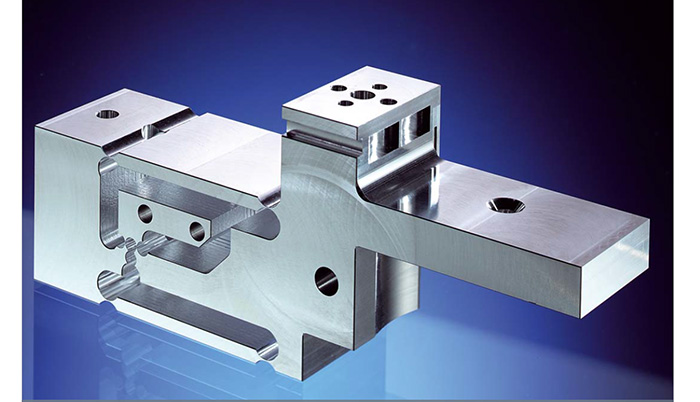

Specifically designed for precision

mould applications, the HWALU range has been developed to combine high strength and

mechanical stability with outstanding machinability. Over the three decades since

the brand's introduction, new HWALU alloys have been developed to satisfy the

enhanced performance requirements of specific moulding technologies, such as

improved weldability and resistance to stress corrosion or sustained high

temperatures.(aluminum plate)

For the specifier, this gives the

reassurance of knowing that the performance characteristics of an HWALU mould plate

will exactly match process requirements every time, with all that implies in terms

of reliable long-term operation. HWALU alloys are supplied fully heat treated, with

no further treatment required.

|

|

|

|

Wide aluminum plate tolerances Guaranteed

Changes in our production process allow HWALU to now guarantee flatness and thickness tolerances on all HWALU tooling and moulding plate. The improved guarantee sets a new industry standard for tooling plate tolerances.Improved stability and consistency

As you kow, stability and consistency are integral to the quality of HWALU plate. HWALU's proprietary chemistry, casting, and production techniques provides excellent piece-to-piece stability and consistency. High stability and consistency reduce warping and movement during sawing and machining. Also, the plate's through-thickness consistency creates fewer metal inconsistencies for easier and faster machining, allowing less rework and fewer scrap pieces. And our superior lot-to-lot consistency means you get the same result time and time again, so youc an develop standard procedures for machining and finishing operations.

Expanded Satin Finish Range

HWALU's genuine satin finish is now available on all tooling plate, the satin finish is twice as smooth as plate with coarse, mechanical finishes. This superior smoothness lets you reduce or eliminate costly surface clean-up operations.Better Identification System

HWALU has also recently updated its marking system. The new method paces product identification on the top of each plate. This new system lets you more easily and accurately identify the select the proper alloy, temper, size and specification. It also helps avoid errors by improving the traceability of sawed blanks.A Quality Commitment

HWALU commit itself to quality processes, products, and performance. This commitment to quality-combined with a strong dedication to our customers-has made HWALU the leader in the aluminum industry. HWALU continuously strives to improve products and processes to meet customer needs and expectations.Guaranteed

The improvements in our wrought tooling plate are one more example of the HWALU Commitment to excellence. The flatness and thickness tolerance guarantee on all HWALU tooling plate, its improved stability and consistency, the expanded satin finish gauge range, the the updated marking system make HWALU's tooling plate the highest quality plate available.

General Specification

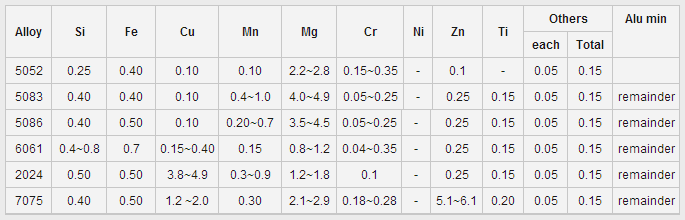

Chemical Composition

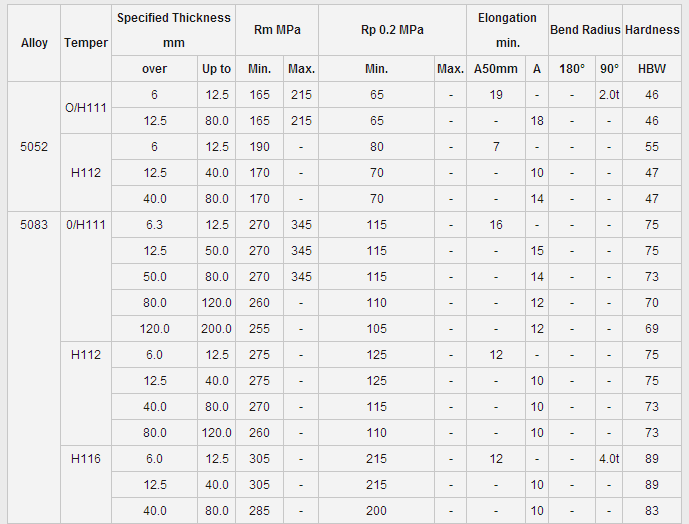

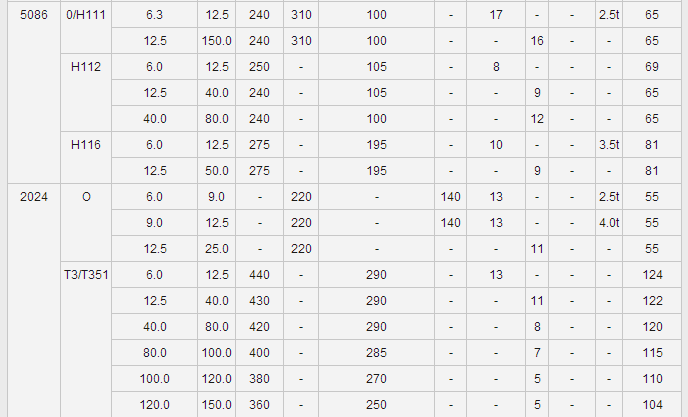

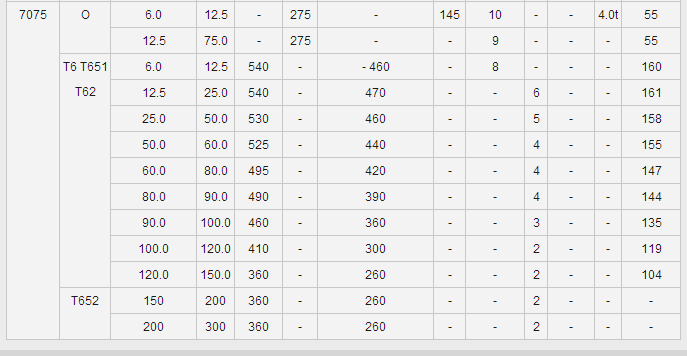

Physical property

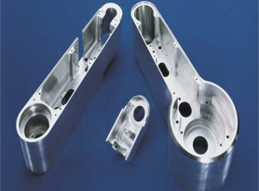

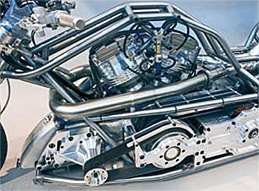

Applications

- *Foam Moulding

- *Vacuum Forming

- *Blow Moulding

- *RIM and Structural Foam Moulding

- *Rubber Moulding

- *Injection Moulding

-

Some of the applications in

which cast plate have been used include food machinery molding plate and other

low pressure molding, electrical heating plate, milling machine bedplate,

automatic inspection machine board holder, and screen printer base

plate.

Wrought aluminum plate products are also widely applied. The nature of the improvements made to the aluminum plate products for use in tool and mold applications involves the following areas:

>> Improved uniformity in through

thickness properties. This is especially important because the aluminum plate products are

available in thickness up to 35" in some cases.

>> Low residual stresses, accomplished by mechanical stress relief

by stretching or cold compression after heat treatment.

>> Excellent flatness

|

|

|

|

|

|

For applications like low

pressure plastic and composite molding including thermoforming and resin

transfer molding that require a material with excellent corrosion resistance and

weldability, 5*** alloys are preferred.

Other applications such as low

pressure molding of rubber and other elastomers, which involve temperatures in

the 350-400 º F range, necessitate a moderate strength materials with good

property retention at moderately elevated temperatures. Here, aluminum plate producers offer

alloys based on the 2*** series.

Another class of applications,

particularly injection and compression molding as well as bolsters and force

plate, call for high strength properties along with excellent machinability,

high polishability, and good shape stability. The 7*** alloy family meets this

need well.

A survey of wrought tool and

mold aluminum plate products would wot

be complete without mentioning moderate strength alloys of the 6*** series.

Specialized versions of 6061 T6 in stress relieved tempers are available both in

plate as compressions tress relieved thick 6061 T651.

While conventional aluminum tool and mold products have some obvious advantages in this these application areas, the competition if not standing still. Some developing technologies include both aluminum ans steel tools manufactured using rapid prototyping methods, which have been trialed in short production run applications successfully. Rapid manufacturing methods eliminate some of the advantages enjoyed by aluminum in terms of machinability and shorter lead times over conventionally processed steel. This area looks like one that will continue to see HWALUficant emphasis and development in the aluminum industry worldwide.