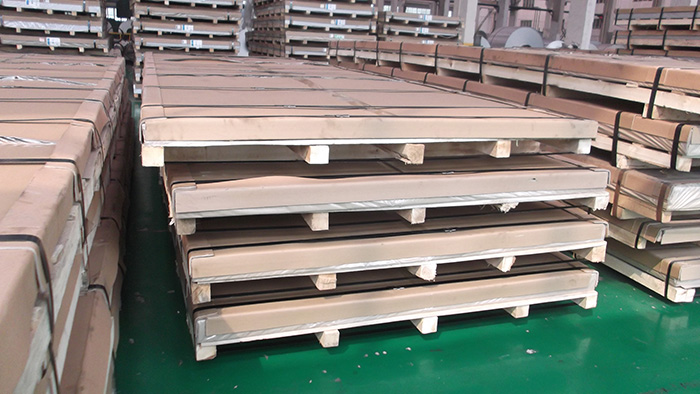

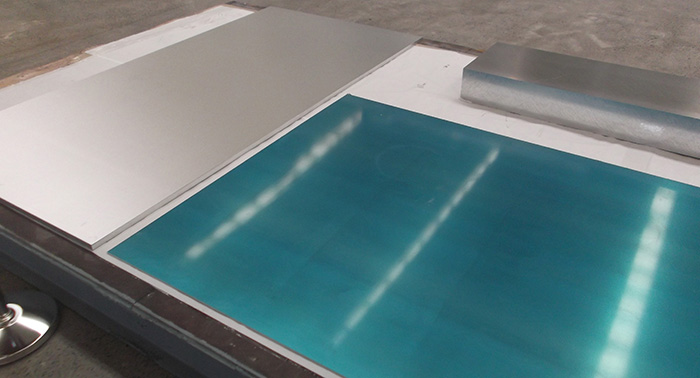

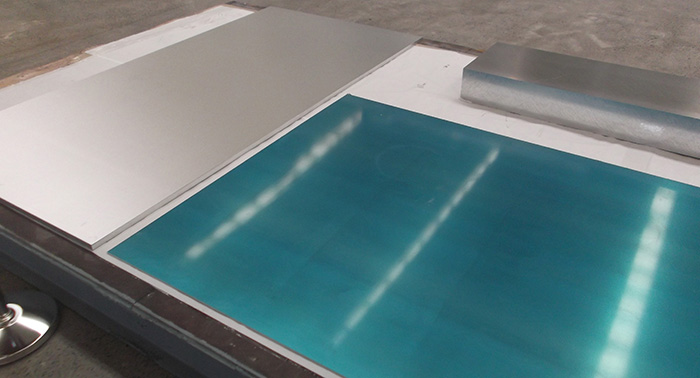

3003 Aluminum Plate Sheet

3003 Aluminum Plate

Sheet

Aluminum alloy 3003 plate sheet is a medium strength alloy with very good resistance to atmospheric corrosion and very good weldability as well as good cold formability. It has better mechanical properties, especially at elevated temperatures than the 1000 series alloys.

Aluminum alloy 3003 plate sheet is a medium strength alloy with very good resistance to atmospheric corrosion and very good weldability as well as good cold formability. It has better mechanical properties, especially at elevated temperatures than the 1000 series alloys.

Aluminum alloy

3003 plate sheet is a non-heat-treatable 1.2% manganese, 0.12% copper alloy

commonly available in flat rolled coil, sheet and plate from a wide range of

producing mills. It is one of the most commonly used of all aluminium alloys,

essentially commercially pure aluminium with the addition of manganese to

increase its strength about 20%. It has all the excellent properties of alloy

1100; excellent corrosion resistance plus the ability to be easily drawn or

spun, welded or brazed. Alloy 3003 is fairly low strength but it

can be hardened to a HWALUficant degree by cold working, enabling a series

of“H” tempers.

Aluminum alloy

3003 plate sheet is also produced as a bright finish tread plate (also known as

checkered plate) with industrial and decorative applications. Aluminum tread

plate in alloy 3003 is typically used in decorative architectural applications,

due to its bright reflective finish. It is usually produced in a

“1-bar” or “ 5 bars” tread pattern. Alloy

3003 tread plate is available

on indent from Atlas.

Aluminum alloy

3003 plate sheet is also available as an “Alclad” product with one

or both sides clad in Alloy 7072;

Corrosion Resistance.

Excellent in a wide range of atmospheric environments, in food and architectural

applications.

Heat

Treatment

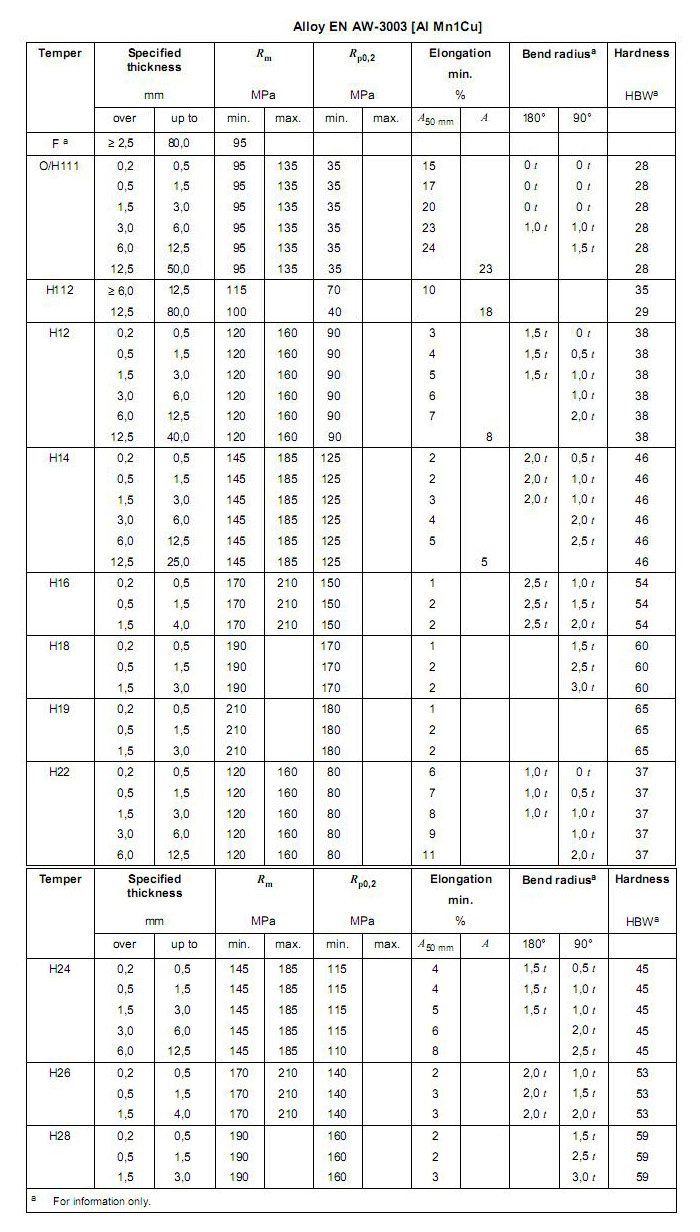

Alloy 3003 is not hardenable

by heat treatment. It can be HWALUficantly hardened by cold work (eg by cold

rolling) and various “H” tempers are produced – most commonly

H12 (¼ Hard) and H14 (½ Hard) – as well as the soft annealed

Temper O condition.

Alloy 3003 is usually

supplied in H1x tempers, where the product is strain hardened only; there is no

stabilisation treatment as is usual for the 5xxx series alloys.

To soften Alloy 3003 it can

be annealed by heating to 415°C, hold until uniform temperature then cool;

the rate of cooling is not important.

Welding

Excellent weldability by all

standard methods; gas, electric and resistance welding. GMAW and GTAW are

preferred and widely used to produce structural welds. Filler alloys are usually

1100 although other alloys are possible. Welding of strain hardened tempers will

reduce strengths in the heat affected

zones.

Machining

Machinability of the softer

tempers O and H12 is poor, with the harder tempers such as H14

and above being somewhat

easier to machine.

Applications: -

Alloy 3003 plate sheet is typically used for:

Building industry

: roofing and sidings, acoustic ceilings,corrugated

sheets

Chemical and food

industries : storage tanks, pipes, metal work

Equipment for heating

and cooling : heat ex-changers, air condition evaporators,

motor vehicle radiators,

freezer linings

Home appliances

: cooking utensils, bakery moulds Office

equipment

Typical

Applications

cooking utensils, decorative

trim, awnings, siding, storage tanks, chemical equipment.

Alloy:

3003

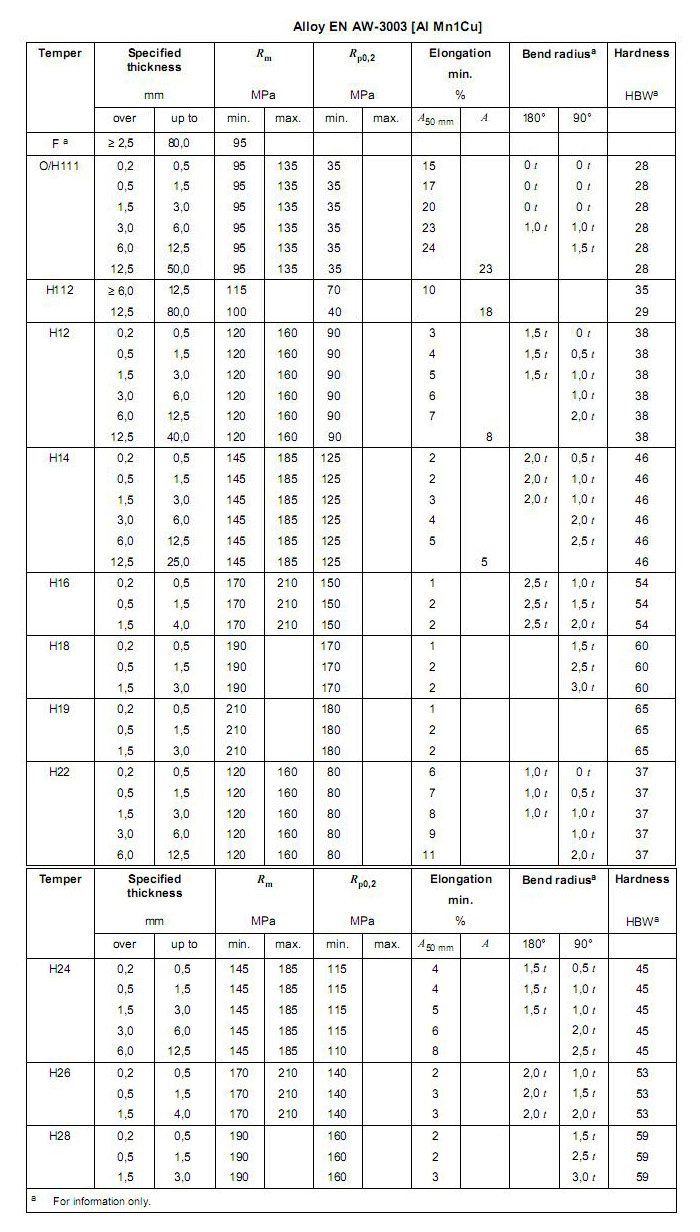

Temper: O, H111, H112,

H12,H14, H16, H18, H22, H24, H26

Thickness:

0.2mm--200mm

With:

500mm--2000mm

Length:

1000mm--12000mm

Surface: Mill finish,

Bright finish, paper interleaved, one side film, both sides film.

Chemical Properties

Chemical Properties

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Ni | Zn | Ti | Ga | V | Others |

Aluminium min. |

|

| Each | Total | |||||||||||||

| 3003 | 0.6 | 0.7 | 0.05-0.2 | 1.0-1.5 | - | - | - | 0.10 | - | - | - | 0.05 | 0.15 | Remainder |